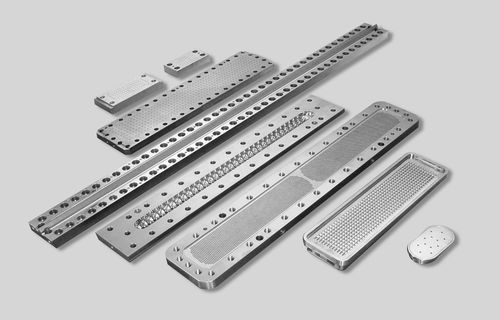

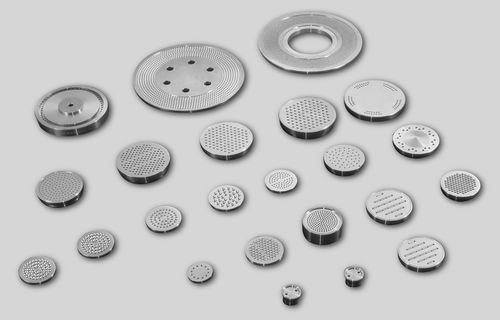

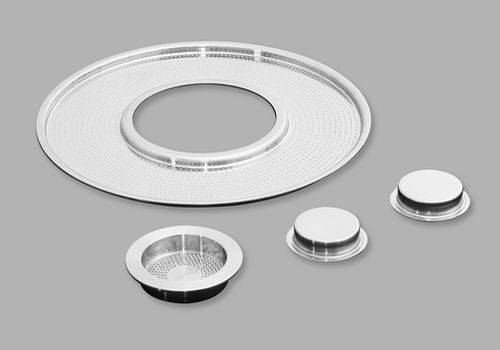

Spinning nozzles, sometimes known as spinning plates, are a type of plate used to form both artificial and synthetic fibers. It has many small holes through which the material is forced. The solution is inspired by examples of natural fiber spinning seen in nature. Many different nozzle shapes and profiles are available, which can be selected for specific production requirements. Various types of materials of construction are available, including stainless steel.

Advantages of

- Wide range of possibilities in terms of choosing the appropriate hole profile.

- Can be used in various textile industries.

- Nozzle materials include stainless steel – DIN, JIS, AISI, AFNOR, among others.

- The surface finish on selected models can be matte, mirror or coated.

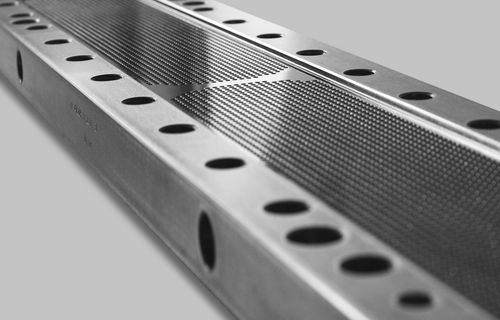

- High level of quality control in the production of nozzles.

Alloy spinning nozzles

Our product range includes all types of high-pressure stainless steel spinning nozzles for spinning monofilaments, multifilaments and staple fibers, including bioplastics, from various polymers such as PP, PA.6, PA.66 and PET used for textile, industrial, carpet (BCF), medical and specialty yarns.

Nozzles and packages for two- and three-component spinning

We supply a full range of two- and three-component spinning nozzles and packages for single- and multi-fiber applications. Components can be designed for specific process line requirements.

Dry and wet spinning nozzles

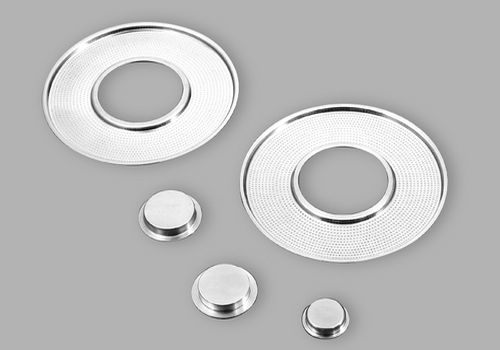

Stainless steel and tantalum components with round or profiled capillaries, such as for carbon fibers and aramids. It is possible to supply different dimensions and forms of the blanks, such as round, cup, ring or oval. The dimensions of the nozzles, their capillaries and forms will be made according to individual requirements.

Nozzles for nonwoven fabrics

Stainless steel nozzles for the production of melt blown or spunbond nonwovens, as well as nozzle strips for the production of hydro-entangled nonwovens, can be manufactured and supplied according to specific needs and specifications, up to lengths of as much as 6 meters.