Spark detectors spark detection systems

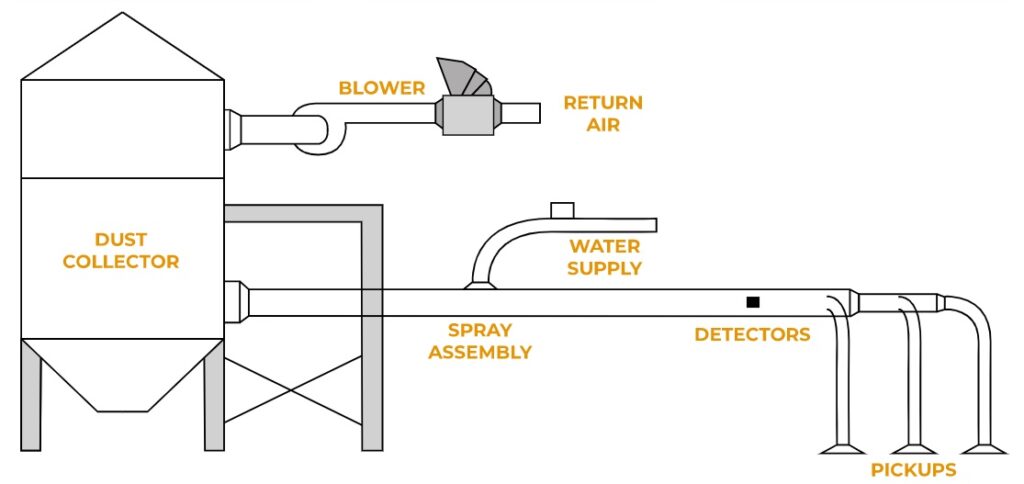

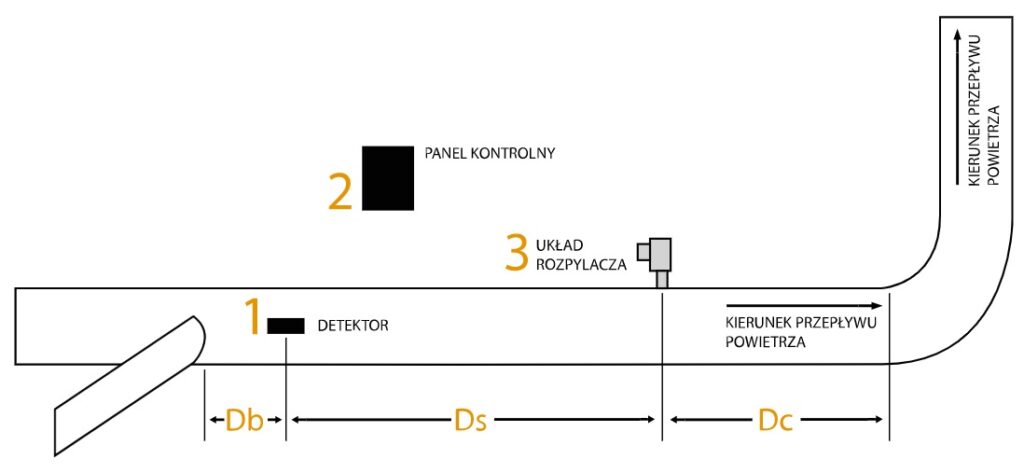

An effective spark detector that monitors all potential paths in the ductwork where sparks or embers may occur. When a spark or ember is detected, a curtain of water is created that they must pass through. Each main duct system is considered a protection zone. If the dust collector has only one main duct, then only one zone is required.

Spark/ember detection systems are most commonly used to protect cutting equipment, belt conveyors, or pneumatic transport lines for bulk materials (e.g., chips, sawdust, cellulose fibers) where there is a risk of explosion or ignition.

Our system consists of the following components:

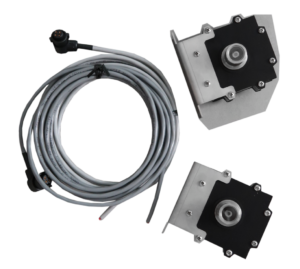

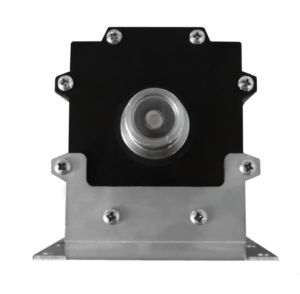

A detector that is highly sensitive to thermal radiation emitted by heated or burning particles. The detector receives an optical signal, which it converts into a digital signal. This signal is then transmitted to a control cabinet, where it is processed and transmitted to the extinguishing system to activate the nozzle.

Spark detectors (spark detection systems) have three distinguishing features in terms of effectiveness:

- They are extremely sensitive to very small amounts of radiation energy.

- Their response time is faster than any other type of detector.

- They are optimized for viewing the near-infrared spectrum.

A spark detection system designed to detect small sparks, hot particles, or smoldering material in cables.

Advantages:

- Response time less than 1 millisecond

- Sensitivity less than 100 nanowatts

- Wide spectrum range

- Wide field of view – 70º on the probe

- Smooth surface for self-cleaning

- FM Approved

Principle of operation:

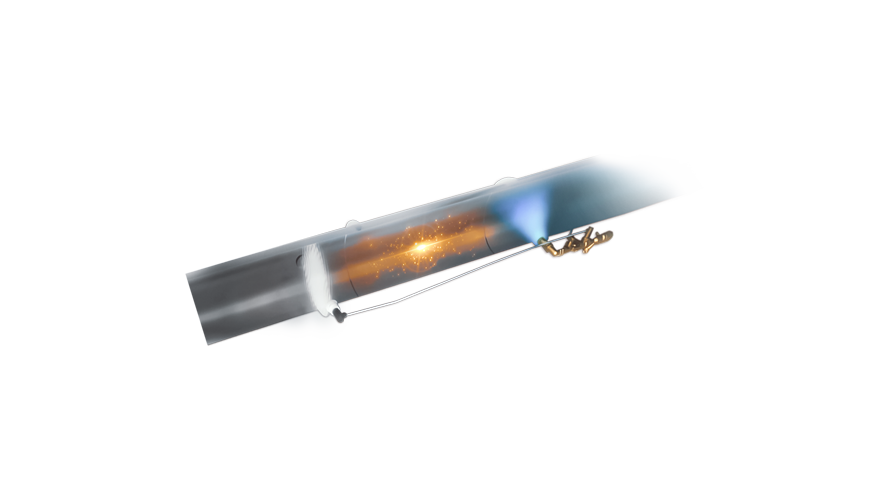

When a spark or smoldering cigarette butt enters the detector’s field of view, the sensor responds by sending an alarm signal to the controller.

Number of detectors:

Depends on the diameter of the pipeline.

Sensitivity test:

When using the Hansentek control panel, it is possible to automatically or manually test the sensitivity of two spark detectors.

It is also possible to perform a test under actual operating conditions – across the entire width of the channel and through both lenses.

Hansentek detectors operate at air velocities of up to 50 m/s. The detector reacts to sudden changes in the optical signal, which is particularly useful when monitoring a channel transporting fast-moving bulk materials. The reason for using the system is to ensure that there is an area in the transport process where the risk of an unnoticed spark is eliminated. It is generally recommended to use two or more detectors to ensure a complete overview of the transport belt.

The spark detection system is used in systems where pneumatic transport of particles is used and where there is a risk of fire or explosion. These include systems that transport materials such as sawdust, cellulose fibers, chemical dust, food ingredients, medicines, or other combustible materials. They are also used in systems where welding fumes are present, in which smoldering particles

or hot material can be carried along with the fumes. The AN6400 can be expanded to 64 zones, but is also competitive with systems that have only one zone. The modular design ensures that you only pay for what you need.

Each zone has its own processor, so adding each additional zone does not slow down the system. Thanks to the intelligent management system, there is no need to create a huge central control unit if there are only one, two, or three zones in the installation. Adding additional zones is very simple: the modules responsible for the zones can be mounted on a DIN rail and the cables connected using plug-in connectors.

The AN6400 is the most versatile system available on the market. It can monitor up to 64 zones and allows you to identify each spark detector in the zone. In each zone, you can also monitor switches responsible for water flow, water pressure, or water line heating systems, as well as heat detectors. When an alarm is detected, the system is able to distinguish whether it is caused by the detection of a spark or heat, which results in various preventive actions being taken, such as spraying water, closing the damper, closing the dust collector, etc.

The AN6400 stores all events in its memory, along with the date and time they occurred. Events can be conveniently viewed on the LCD display built into the control panel. The Hansentek AN6400 spark detector automatically performs a functional sensitivity test of the detectors. When the detectors are mounted opposite each other, the test can be performed automatically or manually under actual operating conditions across the entire width of the channel and through both detector lenses.

The fire extinguishing system uses an electromagnetic water sprayer located below the detection area. The spray nozzle is made of a single piece and, thanks to its design, is highly resistant to clogging.

There are two types of nozzles to choose from: a wide 120-degree nozzle and a narrow internal nozzle. The water sprayer is configured so that potentially hazardous material is guaranteed to be caught in the mist it produces. The spark detector controller ensures the correct moment and time of opening the solenoid valve needed for the spark to pass through the water mist. Activating the sprayer at the right moment ensures that the water mist does not activate too late and does not miss the spark, and that the material is definitely caught in the mist produced. The nozzle has a coefficient

k of 90. This means that it will release 180 liters per minute at 4.5 bar to stop the spread of fire. Depending on the customer’s needs, it is possible to adjust the water spray time. When the system detects a single spark, the extinguishing time is 2 seconds, while for more than one spark, the time can be set to 5, 10, 15, 20, 25, or 30 seconds. After this time, if the detector continues to detect a hazard, the nozzle will remain open until the event is completely extinguished.