| Size | Capacity* [kg/h] | Screen diameter [mm] | Filter area [cm²] |

|---|---|---|---|

| 045 | 90 | 1 x 46 | 1 x 16 |

| 050 | 110 | 1 x 51 | 1 x 20 |

| … | … | … | … |

| 250 | 2700 | 1 x 255 | 1 x 491 |

| 300 | 3900 | 1 x 304 | 1 x 707 |

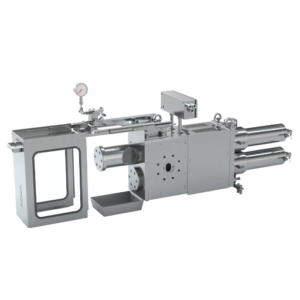

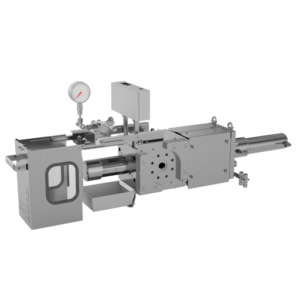

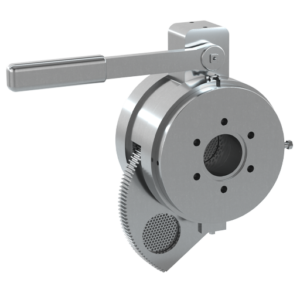

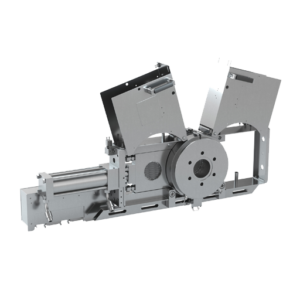

Plate screen changer for extrusion processes

FSC screen changers from Maag are equipped with a pressure-adaptive sealing system as a standard. Thanks to this sealing system, the required sealing forces are adjusted to the actual melt pressure automatically. The narrow design is especially suited for being used in applications with thermally sensitive materials. Their solid and robust construction, available in all sizes and designs, ensures a reliable and leakfree filtration of molten polymers for many years. The hydraulically operated screen changer reliably guarantees the protection of melt pumps and mold gaps from damage and dirt.

Advantages:

- Simple operation and uncomplicated screen changing

- Short material residence time

- Low pressure consumption

- High operational reliability

- Leak-free mode of operation

- Flow channel geometry without any dead spots

Theoretical capacity of the FSC: