| Size | Capacity* [kg/h] | Screen diameter [mm] | Filter area [cm²] |

|---|---|---|---|

| 030 | 80 | 2 x 30 | 2 x 7 |

| 046 | 190 | 2 x 46,3 | 2 x 17 |

| 058 | 300 | 2 x 58,3 | 2 x 27 |

| … | … | … | … |

| 300 | 7800 | 2 x 300 | 2 x 707 |

| 340 | 10000 | 2 x 340 | 2 x 908 |

| 400 | 14000 | 2 x 400 | 2 x 1256 |

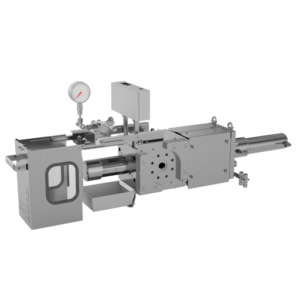

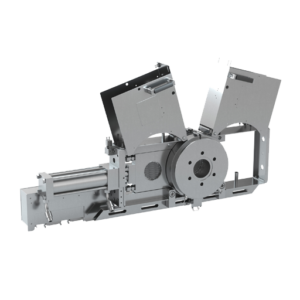

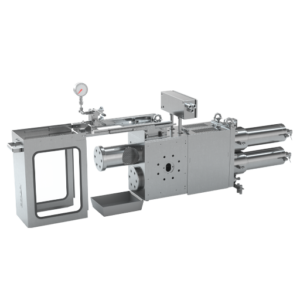

Double piston screen changer for extrusion and compounding

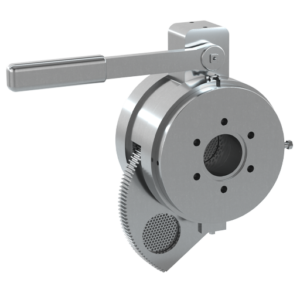

Continuous CSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous screen changers from MAAG increase product quality significantly. CSC screen changers are based on the proven double-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melt for many years.

Suitable for resin & virgin polymer production, masterbatch, compounding, recycling, extrusion, rotomolding, hot melt adhesives.

Advantages:

- Simple operation and uncomplicated screen changing

- Short material residence time

- Low pressure consumption

- High operational reliability

- Leak-free mode of operation

- Flow channel geometry without any dead spots

CSC Theoretical Capacity: