Pulverizers are devices that enable the grinding of plastics used later in various types of processing. It is assumed that pulverization results in particles no larger than 1 mm. Grinding is carried out with the highest efficiency and quality.

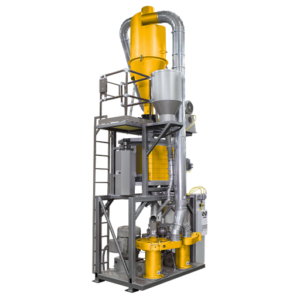

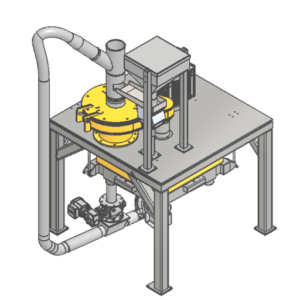

The range of pulverizers available is very wide – from low-capacity units (e.g., for laboratory or pilot applications) to medium- and high-capacity pulverizer systems. The key parameters of the entire process are: the geometry of the grinding disc, the setting of the grinding gap, the feed rate of the input material, the temperature in the grinding chamber, and the thickness of the screen. The devices can operate using both air cooling and cryogenic cooling. MAAG pulverizer systems are characterized by high efficiency in terms of the ratio of kilograms produced to energy consumed. The key element in the pulverization process is the selection of the right machine dedicated to work in specific conditions.