Melt pumps for extrusion

The extrusion gear pump is mainly used in connection with extruders or kneaders. They lower the naturally existing pulsation and uneven transportation, particularly of single-screw extruders.

The extrusion pump is also used as a melt pump. It takes over the establishment of the required transport pressure, which is needed for the downstream equipment.

Efficient pressure build-up

In the gear pump, the pressure build-up occur significantly more efficiently than in the extruder itself. The extruder is relieved through the use of an extrusion pump. Significantly less energy or heat is added to the polymer. The melt pump thereby contributes to the gentlest possible transportation. The EXTRU pump is indispensable for the production of precise foils or micro-granulate.

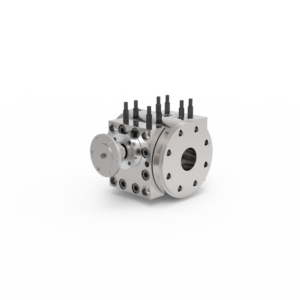

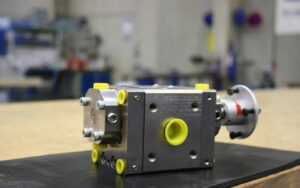

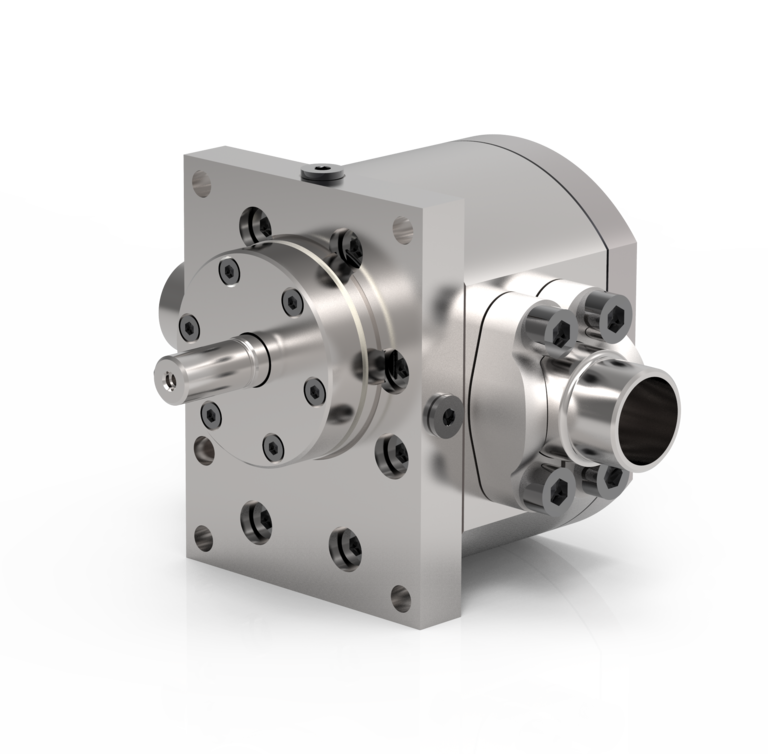

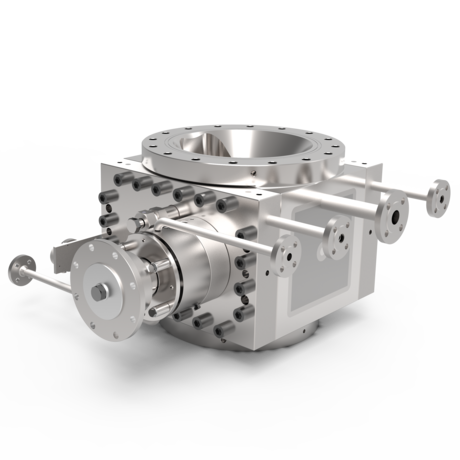

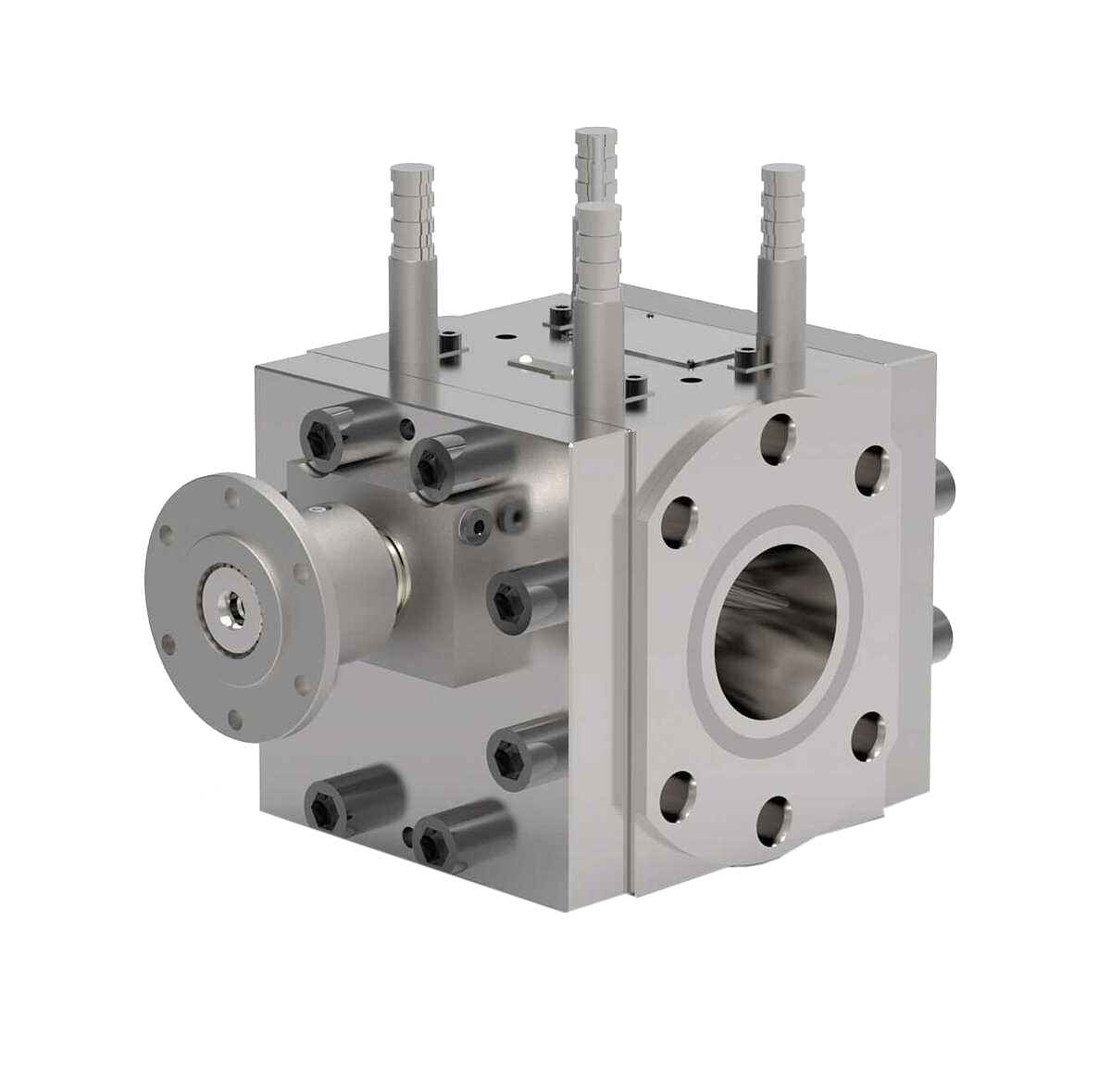

Design examples for melt pumps [EXTRU]

Robust and flexible

The robust design and wear-resistant materials make the EXTRU indispensable for extrusion. It can also be used to transport natural rubber and soft PVC through different special designs.

The WITTE fast-changing color design is perfect for master batch applications with frequently changing colors.

Advantages:

Technical data

| Housing | Heat-resistant carbon steel, for example, 1.6582 · Stainless steel 1.4313 · optional with coating · optional with coating |

| Gear Shafts | Tool steel · Nitriding steel · Special steel · optional with coating · Helical gearing · Herringbone gearing (for transportation with very low pulsation) |

| Shaft seals | Threaded shaft seal · Stuffing box |

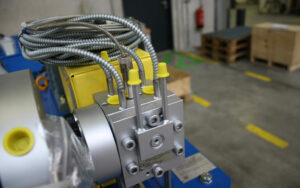

| Heating | Electric through heating cartridges · Cover heating optional |

| Friction bearing | Tool steel · NiAG (nickel-silver) · Aluminum bronze · Special materials · optional with coating |

Operating parameters

| Viscosity | Up to 40.000.000 mPas |

| Temperature | Up to 400°C |

| Suction pressure | Vacuum up to max. 120 bar |

| Transport pressure / differential pressure | Up to 250 bar. Special designs also for higher differential pressures |

| Pump sizes | From 4,7-22-22 (4,7 cm3/U – 10 kg/h) to 12.000-280-280 (12.000 ccm/U). Sizes with smaller gears for higher differential pressures are possible, p.e. 690-140-90. |

Application examples for WITTE melt pumps from the EXTRU series

| Plastics | PS · PET · PVC · PC · PMMA · HDPE · LDPE · LLDPE · PP · PEEK · POLYSULFONS · LICORICE · CHEWING GUM |

Indsutries

Extrusion

Gear pumps for extrusion