The properties of PE depend on the conditions under which the reaction takes place (pressure, temperature, catalyst). Fiber from this material is used, among other things, in the manufacture of bulletproof vests and webbing and reps in climbing and sailing. It is sold under the trade names spectra and dyneema, among others.

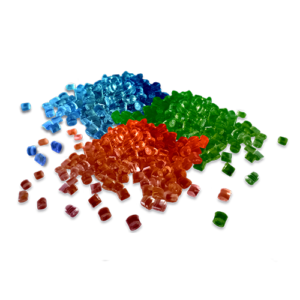

HDPE (high density PE, PE-HD) premix

High-density polyethylene. Obtained by low-pressure polymerization. It is harder compared to PE-LD, has higher mechanical strength, higher melting point (125°C), higher barrier to gases and higher chemical resistance, shows higher brittleness at lower temperatures, is less transparent (milky white). The most popular commercial varieties of PE-HD are PE 80 and PE 100. density – 0.94-0.96 g/cm³.

LDPE (low density PE, PE-LD) premix

Low-density polyethylene – It is transparent, flexible and soft, retains elasticity at low temperature (even down to -60°C), odorless, completely physiologically inert, permeable to gases (oxygen and carbon dioxide) and aromatic substances (odors), while not very permeable to water vapor, susceptible to welding, not very resistant to higher temperatures. Density – 0.915-0.935 g/cm³.

LLDPE (linear low density PE) premix

Low-pressure linear low-density PE (short, unbranched chains are formed by copolymerization of ethene with longer-chain alkenes). Density – 0.915-0.935 g/cm³.

PEX (cross-linked PE) premix

Cross-linked polyethylene, PE chains cross-linked, such as by silanes. Used for pipes and insulation. It is not reversibly thermoplastic.

Premix MDPE (medium density PE)

Medium density. Density – 0.926-0.940 g/cm³.

| Polyethylene – a polymer of ethene (PE) | |||

|---|---|---|---|

| Product name | Properties | ||

| PreMB 61401 HDPE PreMB 61401-40 HDPE | For injection molding/extrusion and special applications. Loading is typically 30%, but 40% is also possible | ||

| PreMB 61801 R-HDPE PreMB 61801-40 R-HDPE | For injection molding/extrusion and special applications. Loading is typically 30%, but 40% is also possible | ||

| PreMB 68801 LDPE PreMB 68801-40 LDPE | For injection molding/extrusion and special applications. Loading is typically 30%, but 40% is also possible | ||

| PreMB 71401 R-LDPE PreMB 71401-40 R-LDPE | For injection molding/extrusion and special applications. Loading is typically 30%, but 40% is also possible | ||

| PreMB 71801 R-LDPE PreMB 71801-40 R-LDPE | For injection molding/extrusion and special applications. | ||