Tanker grounding involves connecting the tank of a vehicle containing flammable liquid, gas or bulk products to the ground so that any accumulated static electricity can safely dissipate into the ground.

This is the primary protection measure used to prevent the buildup of static electricity on the surfaces of tanker trucks and railroads that transport flammable materials. The buildup of static electricity can pose a significant risk of fire or explosion of flammable materials. This makes electrostatic grounding an essential element in the safe and reliable unloading and loading of these materials.

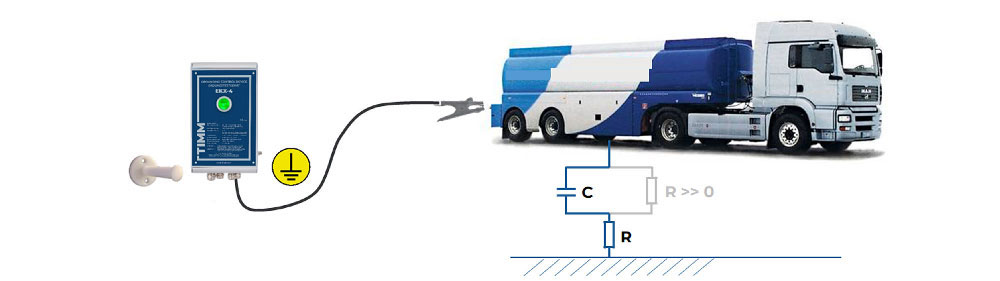

EKX-4 tank truck and rail grounding control system

The system is dedicated to road and rail tank cars. It has an object recognition function by calculating electrical capacitance. The device then sees whether the terminal has been connected to the right place on the tanker barrel or to another metal element. This function avoids misconnection of the grounding terminal – as there are situations in which the driver plugs the terminal not to the barrel, but, for example, to the metal bolts in the wheel or the metal structure connecting the fenders. Systems that do not have an object recognition function after incorrectly connecting the terminal will allow loading or unloading to begin, as the system will then only measure the resistance. Such situations can pose serious risks.

The tank truck detection function that the EKX-4 system has, combined with integrated self-diagnostics, provides a very high level of safety and forces vehicle operators to connect the terminal correctly during each transfer. In turn, an incorrect connection will not allow pumps to start.

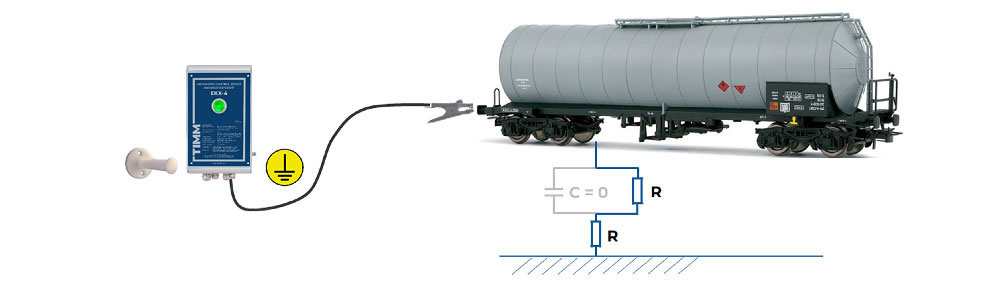

This EKX-4 system can also be used to check the grounding status of rail tank cars, at which electrical capacity is not measured.

Grounding of tank cars

The EKX-4 system is designed to protect unloading stations by monitoring the grounding condition during the filling or emptying process of tank cars in EX zones. The system has an object recognition function by calculating electrical capacitance. If an incorrect grounding terminal connection or loss of grounding is detected, the system does not allow the process to start or continue.

Grounding of railroad tank cars

A system dedicated to the controlled discharge of static electricity from metal rail tank cars during unloading or loading with combustible materials with a process interlock function. Although rail tank cars stand on metal, grounded tracks, many have various types of insulators, such as non-conductive bearings.

The EKX-4 rail tank car grounding control system greatly minimizes the risk of a spark and subsequent fire/explosion in potentially explosive atmospheres, and complies with the requirements of the latest national and international regulations.

What makes up the tank car grounding monitoring system?

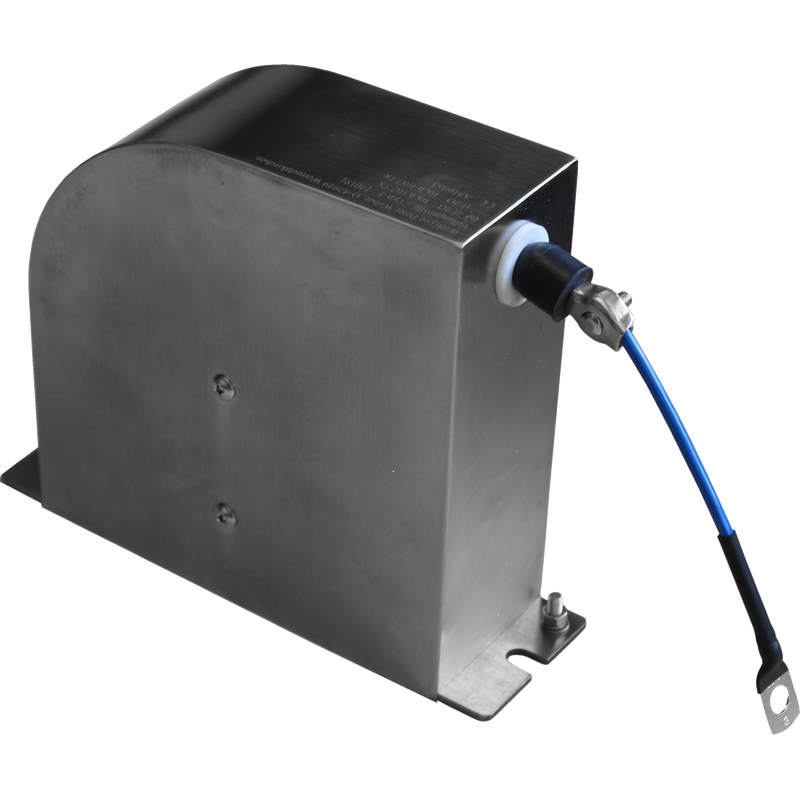

Ex monitoring unit

The grounding resistance tester (monitoring unit) is a device used to measure the resistance of the grounding connection. This measurement determines whether the tanker-ground connection is sufficiently low and, above all, safe. Thanks to the built-in contacts, the monitoring unit has the ability to block the process of filling or emptying the tanker, so you can ensure a high level of process safety and greatly minimize the risk of explosion or fire.

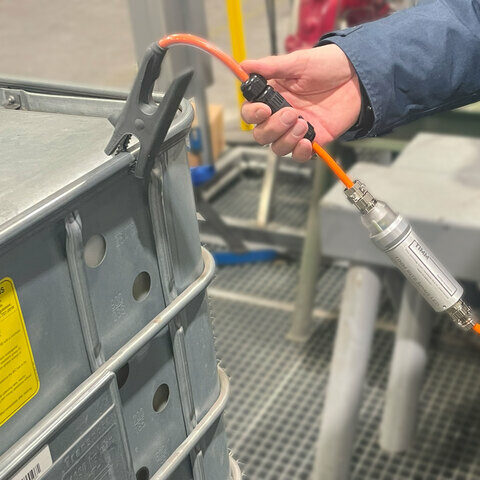

Ex grounding terminals

The grounding terminal is part of the tank car grounding system. It is used to connect the tank car to the ground through a ground wire and a monitoring unit. The clamp is made of stainless steel and has a very strong jaw clamp. It is designed to ensure safe and effective discharge of accumulated static electricity from the vehicle’s barrel, reducing the risk of explosion in the event of electrostatic discharge during the implementation of the loading or unloading process in hazardous areas.

Grounding conductors

The grounding conductor is another part of the grounding system. It usually appears as a spiral cable, optionally it can be wound on a spool/drum. For comfort reasons, straight wires that tangle on the ground are the least common. The core of the cable is usually made of a good electrical conductor, while its sheath is made of a special material resistant to all kinds of chemicals.

Tanker grounding is extremely important because, by properly dissipating static electricity, it prevents dangerous discharges that can be the source of explosions and fires. Therefore, it is important to ensure that tank cars are properly grounded when unloading and loading flammable liquids and bulk products that have explosive properties. In this way, dangerous accidents can be prevented.

To ensure proper grounding of tank cars, follow safety standards and regulations and use dedicated grounding systems, preferably with monitoring of the current grounding status and the ability to block the process. Many countries have their own regulations on tank car grounding, which must be strictly followed. In Poland, there are regulations and standards that specify requirements for protection against static electricity hazards.

Tank car grounding uses systems that include a certified grounding terminal, a cable and a unit that monitors the grounding condition. The clamp is connected to a dedicated location on the tanker barrel marked “grounding.” The monitoring unit checks the correctness of static discharge in real time. In order to increase the level of safety, it is recommended to use tank car grounding systems that have a function to block the loading or unloading process when grounding is not carried out correctly.

When grounding tank cars, avoid connecting the terminal to places that are not intended for this purpose, for example, to the metal structure under the barrel of the vehicle (the barrel is isolated from the rest of the vehicle). Such behavior results in the lack of correct grounding of the tanker. To avoid such situations, modern systems have the function of detecting the barrel by calculating the electrical capacity. This makes it impossible to unload or load the tanker if the grounding system terminal is not connected correctly.