Handling bulk substances in technological processes, such as flour or sugar, for example, creates a dusty, flammable explosive atmosphere. Pneumatic conveying, mixing or transferring generate a very large amount of electrostatic charge, and combined with the low ignition energy of many substances can lead to dangerous incidents.

In order to minimize the risk of ignition that can be caused by spark discharge, it is recommended to use active ground control systems for process plants and nylon big bags, since bulk products are most often packed and transported in such.

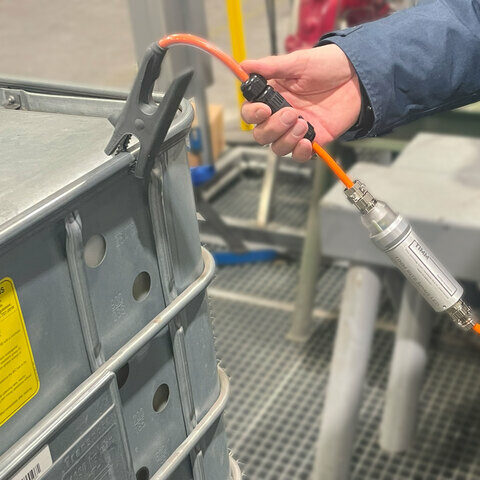

It is important that Big Bag bags are C-type – this means that inside the entire bag is interwoven a metal line, which picks up electrostatic charges from the medium, which in turn can be discharged to earth.

In the event of a sudden loss of grounding by loosening a terminal or being knocked down by a worker, the system detects the error, enters the NO END mode and sends a signal to the control cabinet to stop the process. It can be restarted only after the grounding clamp is reattached.

Working principle of EKX-FIBC flexible big bag grounding system

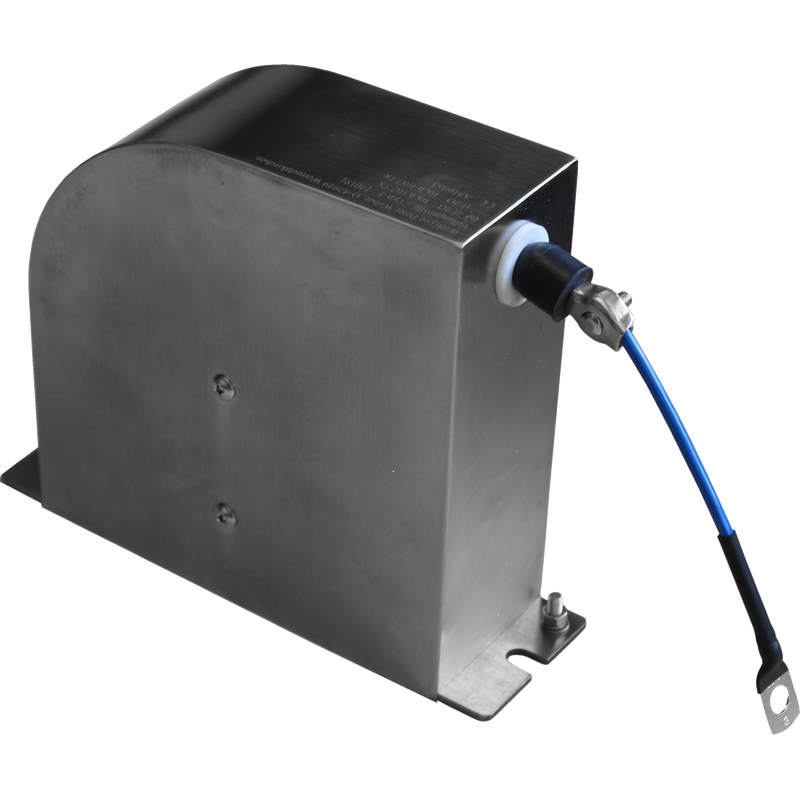

The EKX-FIBC grounding control system is dedicated to C-type nylon Big Bags, discharges charges from them and continuously monitors the resistance. Such a system is equipped with potential-free contacts that start the bag filling process or interrupt it if grounding is lost during filling.

Advantages of the system

- Ongoing monitoring of the correctness of the grounding status during ongoing processes

- Interlocking of the process in case of detection of lack of grounding of big bags

- Quick installation, easy commissioning and comfortable use

- Functional safety (SIL 2)

- Modern explosion protection concept (IEPC)

Components of the EKX-FIBC flexible big bag grounding system

- Ex-compatible grounding monitoring unit (has potential-free contacts to enable process interlocking in the absence of grounding and activation of a light/sound alarm)

- Ex and NAMUR-compatible control outputs that allow the system to be opened in the hazardous area when changing cables, for example

- Two grounding terminals with wire (the terminal has special teeth that do not destroy the bag material)

- A set of Ex glands

- Optionally, the system can be equipped with an intermediate module that allows the grounding terminals to be up to 20 m away from the monitoring unit

Certifications of the EKX-FIBC flexible big bag grounding system

- Ex II 2 G – Ex eb ib q IIB T4 Gb

- Ex II 2 D – Ex ib tb IIIC T80°C Db