Processes at risk of electrostatic discharge include, but are not limited to, processes such as emptying/filling IBCs and metal drums/tanks, transferring, batching and mixing.

If the above-mentioned processes handle media that cause flammable explosive atmospheres, be sure to use certified ground control systems that safely and continuously discharge electrostatic charges to ground and measure resistance levels.

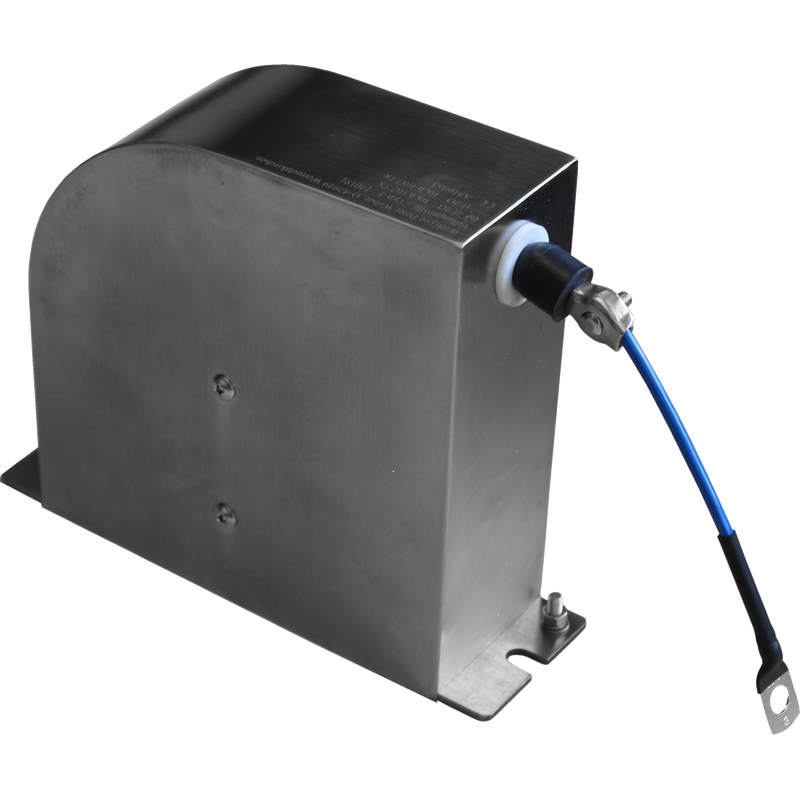

Principle of operation of the EKX-4 2POLE process plant grounding control system

Using EKX-4 2-POLE process plant grounding control systems, the user gains visual confirmation through the illumination of a green indicator light that the tank or process plant has an acceptable resistance for operation.

In the event of a sudden loss of grounding through a terminal coming loose or being knocked down by a worker, the system detects the error, enters the NO ENABLE mode and sends a signal to the control cabinet to stop the process. It can be restarted only after the grounding terminal is reattached.Components of the EKX-4 2-POLE process plant grounding control system

- ex-compatible grounding integrity monitoring unit with potential-free contacts for process interlocking in the absence of grounding and activation of a light-sounder,

- nAMUR-compliant Ex control outputs that allow the system to be opened in the hazardous area when changing cables, for example,

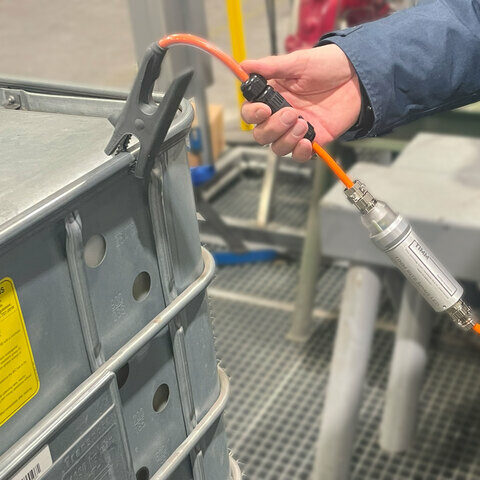

- certified stainless steel grounding terminal in Ex,

- spiral grounding cable in various lengths or straight cable on Ex self-retracting spool – cable sheath resistant to many chemical and atmospheric agents,

- a set of Ex glands.

Certifications of the EKX-4 2-POLE process plant grounding control system

- Ex II 2 G Ex eb q [ib]

- Ex II C T4 Gb

- Ex II 2 D Ex t [ibD] IIIC T80°C Db

- Compliance with EU directive 2014/34/EU (TÜV certificate 11 ATEX 080882)

- SIL2