applicable in explosion hazardous areas and are used to ground conductive elements of technological installations.

Technical solutions of electrostatic grounding allow the discharge of electrostatic charges from tank cars, railroad tank cars, IBC tanks, metal containers, drums, carts and other technological equipment (e.g. mixers) or their instrumentation components, which can become electrified and pose a serious danger. A selection of them monitor grounding status in real time.

There are two most important product groups:

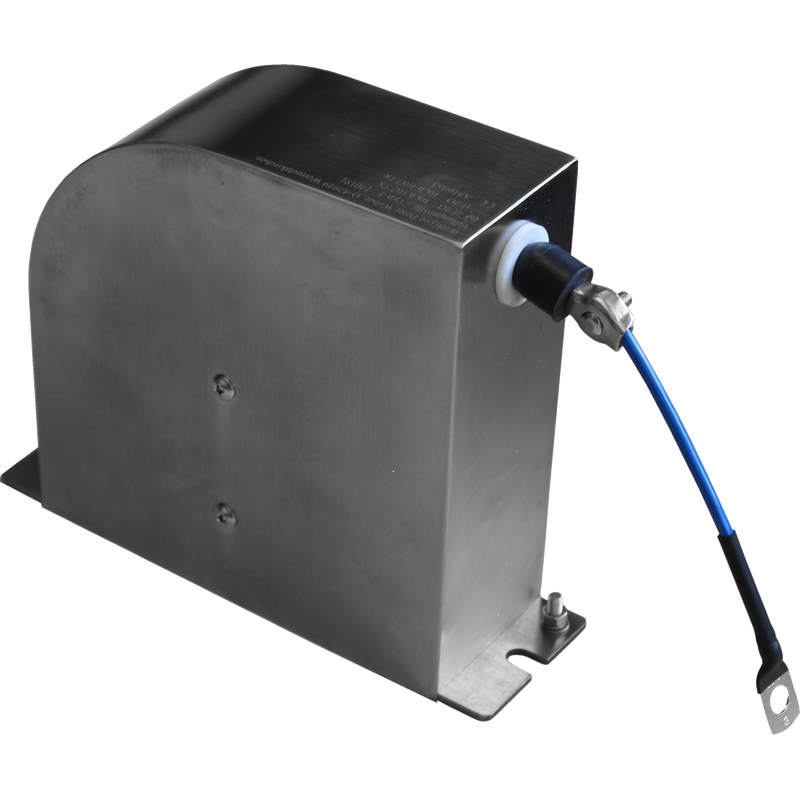

- systems designed for monitoring and ongoing control of grounding status,

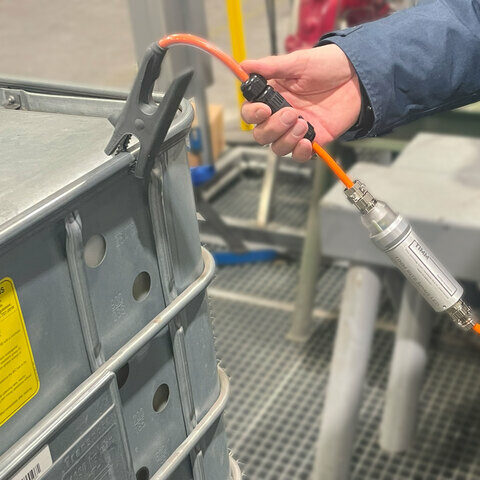

- grounding clamps (also known as clamps, pliers, pincers, earthing clamps, crocodiles) equipped with single- or two-wire cables – used for dissipation of electrostatic charges.

Electrostatic discharge is one of the potential ignition sources of explosive atmospheres. In view of this hazard should not be ignored by plant services and business owners. By implementing appropriate electrostatic safeguards, the following can be avoided or reduced among others:

- the danger associated with the possibility of fire and/or explosion in the industrial facility or on its premises (which can occur enough when the energy of the electrostatic discharge reaches a value at least comparable to the minimum ignition energy of the flammable substance/agent (MEZ) occurring or likely to occur in the area),

- disturbances in the course of ongoing technological processes affecting the quality of manufactured products products and resulting necessity of technological breaks generating additional costs,

- mishaps endangering the health and life of plant personnel.

Electrostatic protection (a.k.a. anti-electrostatic, anti-static) measures are designed to are aimed at eliminating hazards arising from the generation and accumulation of electrostatic charge. In particular, they should be implemented in enterprises where there are zones of danger of explosion and which, among other things:

- implement processes such as, for example, batching, mixing, pouring, transferring products flammable,

- receive explosive liquid substances or bulk materials (such as sugar, flour) via tanker trucks / dump trucks / railroad tank cars (processes of loading/unloading).

- Protecting the health and lives of personnel during their duties by preventing accidents caused by electrostatic discharge phenomenon

- Significant impact on the appropriate level of safety and working conditions

- Protection of plant property by reducing the risk of ignition of flammable atmosphere as a result of the jump of an electrostatic spark electrostatic spark, the consequence of which can be a dramatic fire or explosion

- Safety and reliability of processes carried out in the daily operation of enterprises industrial

- Fulfillment of the obligation to implement protection against static electricity in potentially explosive atmospheres explosion, which results from the requirements of the ATEX Directive 2014/34/EU, ATEX USERS 199/92/EC and current national regulations