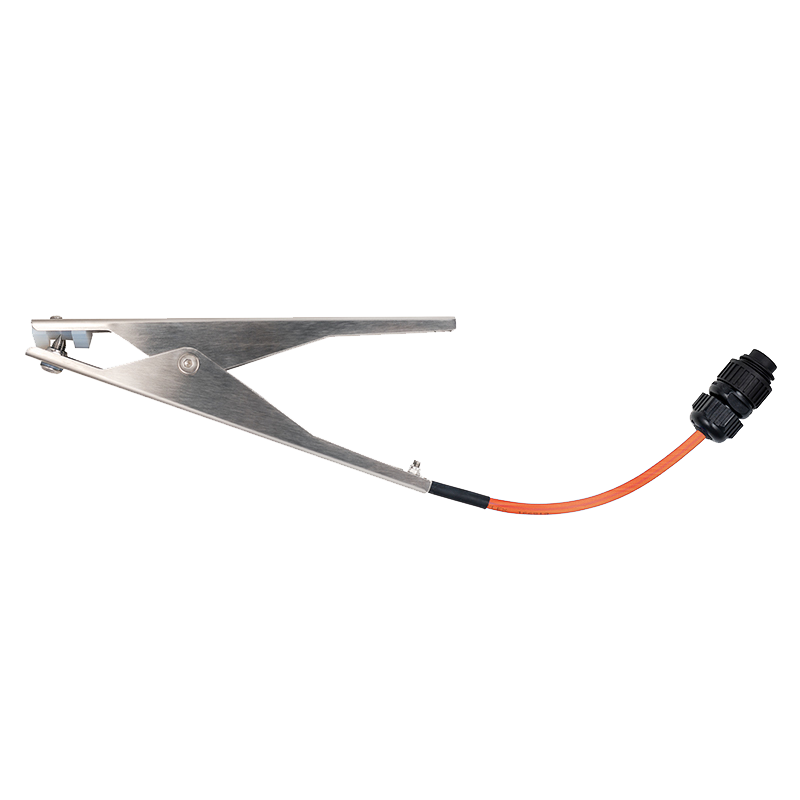

EX grounding clamps

Grounding terminals are used to dissipate electrostatic charges from metal tanks, drums, mixers and tanks during the loading and unloading process. Their purpose is to provide a permanent connection between the item to be grounded and the ground, preventing the build-up of electrostatic charge and minimizing the risk of explosion or fire.

Grounding clamps usually come complete with a grounding spiral cable. The clamp is made of stainless steel and has very sharp teeth that pierce through a layer of paint or rust, providing a permanent connection to the metal surface. The grounding cable is made of copper or steel, which is a good conductor. It is also insulated thanks to a special coating that is resistant to many mechanical and chemical agents.

During technological processes such as mixing, pouring or loading or unloading of tanks, grounding terminals should be attached at dedicated locations. Depending on the type of process or the safety requirements of a particular industrial plant, grounding clamps alone with a wire are used, or complete grounding systems that, in addition to the clamp and wire, also have grounding condition monitoring units.

Grounding clamps are very important for ensuring the safety of loading and unloading processes of tank trucks and railroads, as well as other technological processes in which flammable substances are handled. All components to which the grounding terminal is connected must be in good condition to ensure a permanent connection and reliable discharge of static electricity. It is also important that grounding terminals are regularly inspected and replaced when they are damaged or defective.

– ex grounding terminals for tanks,

– Ex grounding terminals for metal drums and containers,

– Ex grounding terminals for IBC tanks and type C big bags,

– Ex mini grounding terminals,

– Ex magnetic grounding terminals

Optionally, the terminal can be equipped with a nitrile rubber insulating shield to protect it from chemical agents and weather conditions. The shield is resistant to high temperatures and mineral oil-based substances.

In addition, we provide pins made of plastic for hanging the terminals. For the above applications, the clamps are connected to ground wires. They are also part of complete systems for monitoring the state of grounding.