Underwater granulation system for high-volume production with throughputs as high as 36,000 kg/h

Range of applications:

SPHERO® granulation systems are ideal for the production of raw materials as well as blends, pre-mixes and recyclates based on:

- polyolefins, such as: LDPE, HDPE, PP

- styrene polymers, e.g.: PS, SAN, ABS

- acrylic resins, e.g.: PMMA, PAN

- polyacetals, e.g.: POM

- polycarbonates, e.g.: PC

- polyesters, e.g.: PET, PBT, PEN

- polyamides, e.g.: PA 6, PA 6.6, PA11, PA 12

- thermoplastic elastomers, e.g.: TPE-S, TPE-E

- polyurethanes, e.g.: TPU

- hot melt adhesives

- rubbers

- natural and synthetic resins

- biopolymers, e.g.: PLA, PHA, Bio-PA, Bio-PET, Bio-PP

- other plastics

SPHERO® granulators – Benefits:

- Excellent granule quality

- Increased production efficiency

- Increased process reliability

- Optimum accessibility

- Convenient and safe operation

- Possibility of quick changeover of the machine

- Granulation of specialized products

Operating principles of the SPHERO® system:

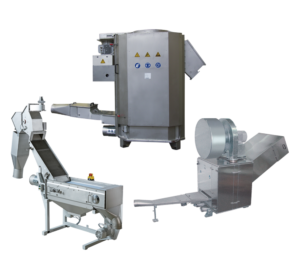

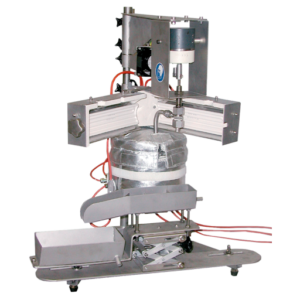

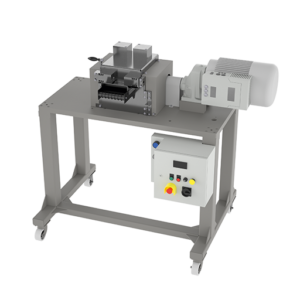

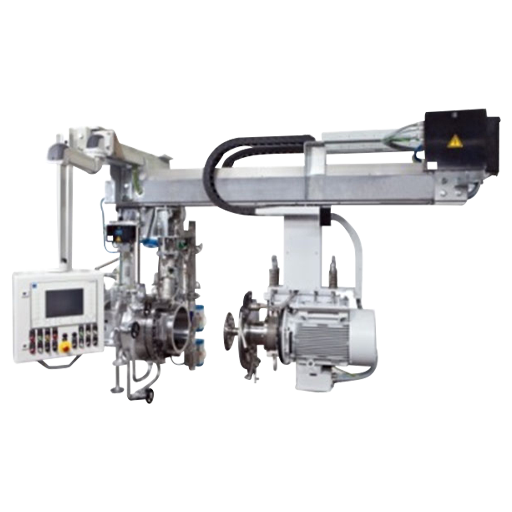

The melted plastic is transferred to the die plate via a hydraulic starting valve (01). On the heated die (02), the melt is distributed to holes arranged in a ring shape and forced into the cutting chamber (03), which is flooded with industrial water. The head on which the knives are mounted is directed to the die plate, where the polymer is cut into granules, which in turn, with the help of industrial water, are transferred to the dryer (04). In the dryer, the granules are separated from the water and transported for further processing (05). The industrial water is filtered, brought to the right temperature and poured back into the cutting chamber (06).

Description:

Being the most reliable and competent partner in the field of underwater granulation, Automatic Plastics Machinery provides perfectly customized systems. Through close cooperation, we can find the best and most cost-effective solution for you. The components of our system are reliable, durable, very easy to operate and designed to optimize the granulation process.

The well thought-out concept of suspended components is the main and greatest advantage of the device. Various setting options and the possibility of using different accessories complete the picture of this system.

Considering all possible underwater granulation systems, the SPHERO is the system with the easiest access. Thanks to the suspended granulator components, the operator can control the system quickly, easily and safely.

The processes, equipment and systems developed by Automatik Plastics Machinery are characterized by flexibility, cost-effectiveness and superior reliability. With more than 60 years of experience and having installed more than 8,000 granulation systems, our staff will help you select the most profitable solutions for you.