Highest quality threaded underwater granulation system

Range of applications:

M-USG® systems are used for granulation of technical thermoplastics such as:

- polyesters, such as: PET, PBT, PEN

- polyamides, e.g.: PA 6, PA 6.6, PA11, PA12

- acrylic resins, e.g.: PMMA, APN

- polyacetals, e.g.: POM

- polycarbonates e.g.: PC

- styrenic polymers e.g.: HIPS, GPPS, ANS, SAN

- polymers of liquid crystals

- other plastics – on request

M-USG® granulators – Benefits:

- Consistent, excellent granule quality

- Throughput rates of up to 20,000kg/h

- Increased system availability, thanks to a quick-attach cutting head

- High degree of automation

- Long service life due to the use of extremely wear-resistant cutting tools

- Ease of operation and good access to perform maintenance

- Highest reliability

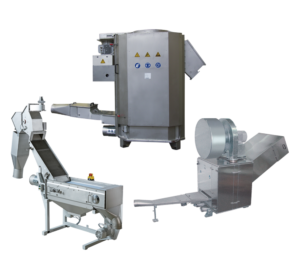

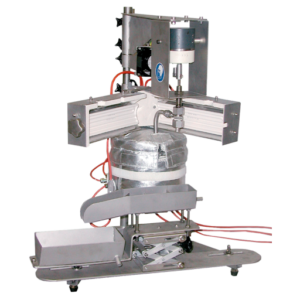

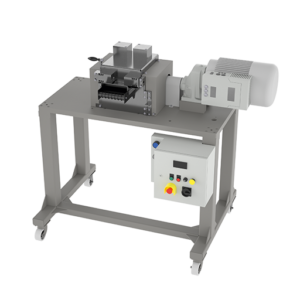

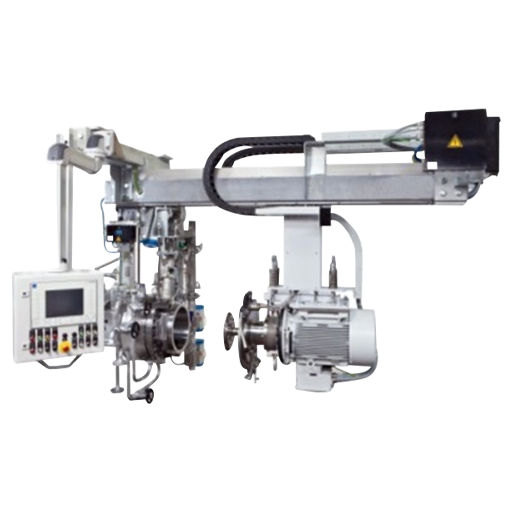

Operating principles of the M-USG® system:

Molten plastic is fed to the extruder head (01). The material is then pressed through the die to form polymer threads. The strands are automatically guided by the starting device to the guiding section (02), then they are carried by a stream of water flowing in parallel to the granulator and cooled by water from spray nozzles. In the granulator (03), the polymeric strands are automatically captured by a gripper, delivered to a cutting device, and there cut under water into granules. Immediately after cutting, the granules are flushed to the subcooling lines (04), where they are cooled to the appropriate temperature. A sinter separator separates the starting material from the well-formed granules, thus preventing clogging of the dryer inlet. In the dryer (05), 95% of the water is removed by means of a pre-dewatering system; the remainder is removed as the granules continue to be transported through the dryer. The granules are then screened and transported for further processing (06). The process water is filtered and brought to the proper temperature in a water conditioner (07) before being returned to recirculation.

Description:

Thoroughly pretested and approved underwater thread granulation systems are designed for medium- and high-volume production and for the production of top-quality cylindrical granules. A key element of the system is the very high level of accessibility to the system. All system components – such as the head, die, runner, subcooling line, dryer and sifter – are designed to meet all your requirements for process continuity and safety.