High-performance underwater strand granulation system designed for economical production

Scope of application:

P-USG underwater thread granulation systems are mainly used in the processing industry, where throughput does not exceed 6,000 kg/h. P-USG systems are also suitable for processing mixtures with fillers. Recyclates from:

- polyesters, e.g.: PET, PBT

- polyamides, e.g.: PA 6.6

- polycarbonates, e.g.: PC

Thermoplastics and bulk plastics with fillers:

- PP, PE 20-60% talc, carbon black or “titanium white” TiO₂

- other plastics – on request

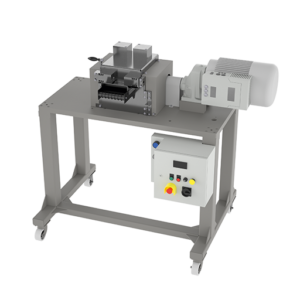

P-USG® granulators – Benefits:

- Consistent, excellent granule quality

- Simple operation

- Automatic thread blending at start and during production

- Operating speed of up to 250 m/min

- Excellent quality of cutting tools and conveyor components

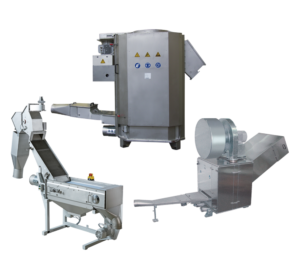

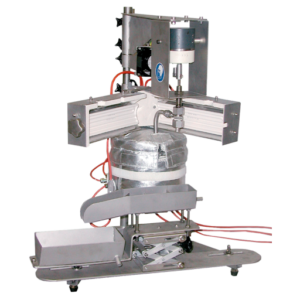

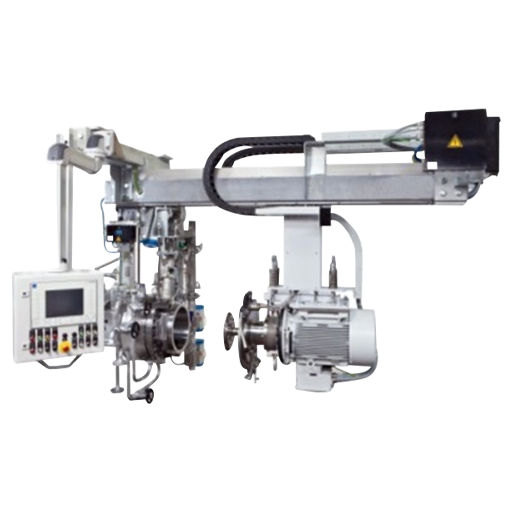

Operating principles of the P-USG® system:

The polymer threads flowing out of the die (01) are fed onto the guide (02), which is manually adjusted before start-up. From there, the threads are transported by water to the granulator. During transport, the water cools the threads. In the granulator (03), the polymeric strands are gripped and fed to the cutting device, where they are cut into pellets under water. The suspension of granules and water is transported to the subcooling line (04). Here the granules are cooled to the required temperature. In the dryer (05), the granules are separated from the water and dried. The granules can be divided and transported for further processing (06). The process water is filtered and brought to the appropriate temperature in the water treatment unit (07) and recirculated.

Description:

With more than 60 years of experience in the field of underwater strand granulation systems, Automatic Plastic Machinery provides the right solution for individual customer needs. P-USG underwater granulation systems are characterized by high operating speed and throughput, thus ensuring high efficiency, which is especially highly shaded in the processing and recycling area. The system is characterized by a very simple start-up process and the production of excellent quality cylindrical granules. One of the main advantages of the P-USG system is the increased accessibility to all components of the system, such as the extruder, guide section, subcooling line, dryer and sifter. All of these system components must meet your production requirements as well as the highest quality standards in terms of the form of granules obtained and the reliability of the process.