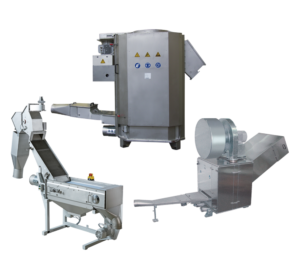

Drop granulation system used to obtain perfectly spherical dust-free granules

Range of applications:

The DROPPO® drop granulation system is ideal for use with low-viscosity dispersions and liquids whose viscosity is less than 500 mPas:

- plastic preproducts such as:

- dimethylterephthalate,

- bisphenol A,

- maleic anhydride,

- carbamide

- low-viscosity plastics, e.g:

- PET

- additives in the plastics industry, e.g.:

- light and hot stabilizers,

- lubricants,

- active agents

- active substances in the food industry and in the production of spices, such as:

- hermetically sealed products

DROPPO® granulators – Benefits:

- Ideal for low viscosity materials and for liquids

- Obtaining perfectly spherical dust-free granules is guaranteed by uniform material conveying and due to the high bulk density of the folding, as well as accurate downstream dosing

- The drop unit can be integrated into existing lines, such as spray towers, etc.

- high profitability achieved through reduced energy consumption and low manpower requirements

- Quick and easy conversion to other production

- No possibility of mechanical wear and tear

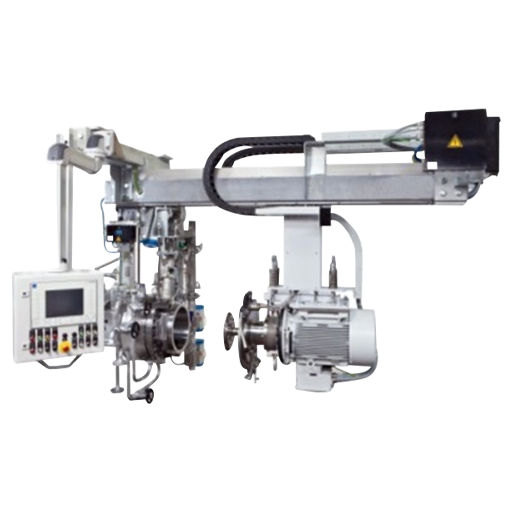

DROPPO® system operating principles:

The low-viscosity substance or liquid is discharged from the feeder (1), filtered (2), and from there transported to the discharge device (3). There, the product is distributed to the die plate and pumped through the concistetically arranged die openings (4). As a result of harmonic vibrations, remarkably homogeneous droplets are separated from the sustance. The surface tension forms the droplets into perfect spheres during free fall. During descent, these droplets are subjected to solidification (5) by passing through a layer of cooling gas (air, nitrogen). This can also be achieved by immersing them in water. The coagulated DROPPO droplets are transported for further processing (6). The cooling medium is filtered, brought to the appropriate temperature and recirculated (7)

Description:

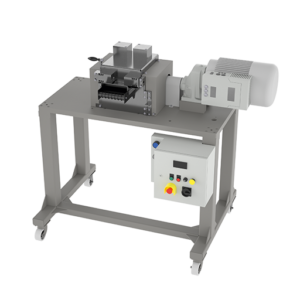

Automatik Plastics Machinery offers the perfect solution for your individual requirements: DROPPO Mini for the development department and for use in the laboratory, DROPPO 50 used for small and medium-sized production lines and DROPPO 300 for large-scale production. The DROPPO Mini test device allows you to check and prepare the relevant process parameters before starting full-scale production. It also makes it possible to produce a trial batch of material. The device is equipped with a replaceable one-hole die and allows you to perform a significant number of tests having only three liters of material. The DROPPO Mini is an excellent complement to the DROPPO system used for full-scale production.