Granulators for plastics

The modern world uses plastics in virtually every field, which are subject to damage or destruction during operation, use. In maintenance and repair work carried out with plastics, it is extremely important to recognize what type of plastic you are dealing with.

It is the type of plastic that determines the choice of solvent, adhesive or varnish that can be used. If damaged, plastic parts usually end up in the trash. This, however, entails the creation of a huge amount of waste – from various types of disposable packaging, to everyday items, to parts of machinery, equipment and structures. Since plastics are among the materials that are very difficult to decompose, and landfills have limited capacity, one should seriously consider the problem of their reuse.

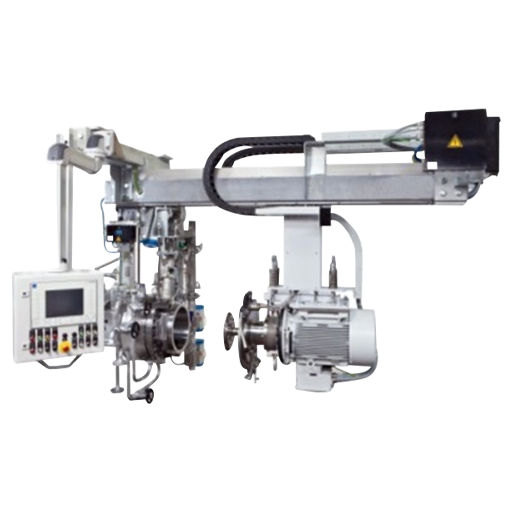

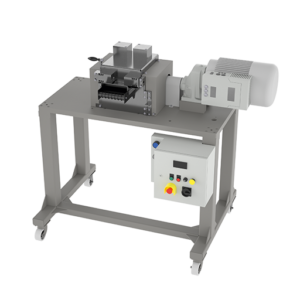

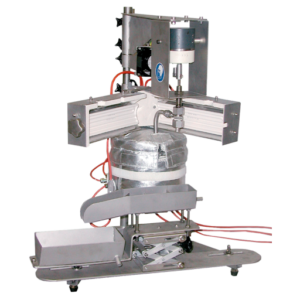

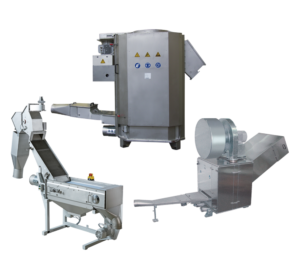

Plastics in granular form are widely used in many plastics processing operations, which primarily use single-screw plasticizing systems. Heat granulation extrusion involves extruding many identical rods of small-diameter plastic with immediate rotary non-volatile cutting into short lengths. The cutting of the extrudate and the cooling of the granules can be carried out in the cutting chamber of the granulation head in a stream of air or water. The choice of the appropriate granulation process depends mainly on the rheological and thermal properties of the polymer, productivity, power consumption, process reliability and wear issues of the various process line components, as well as the intended use of the resulting granulate.