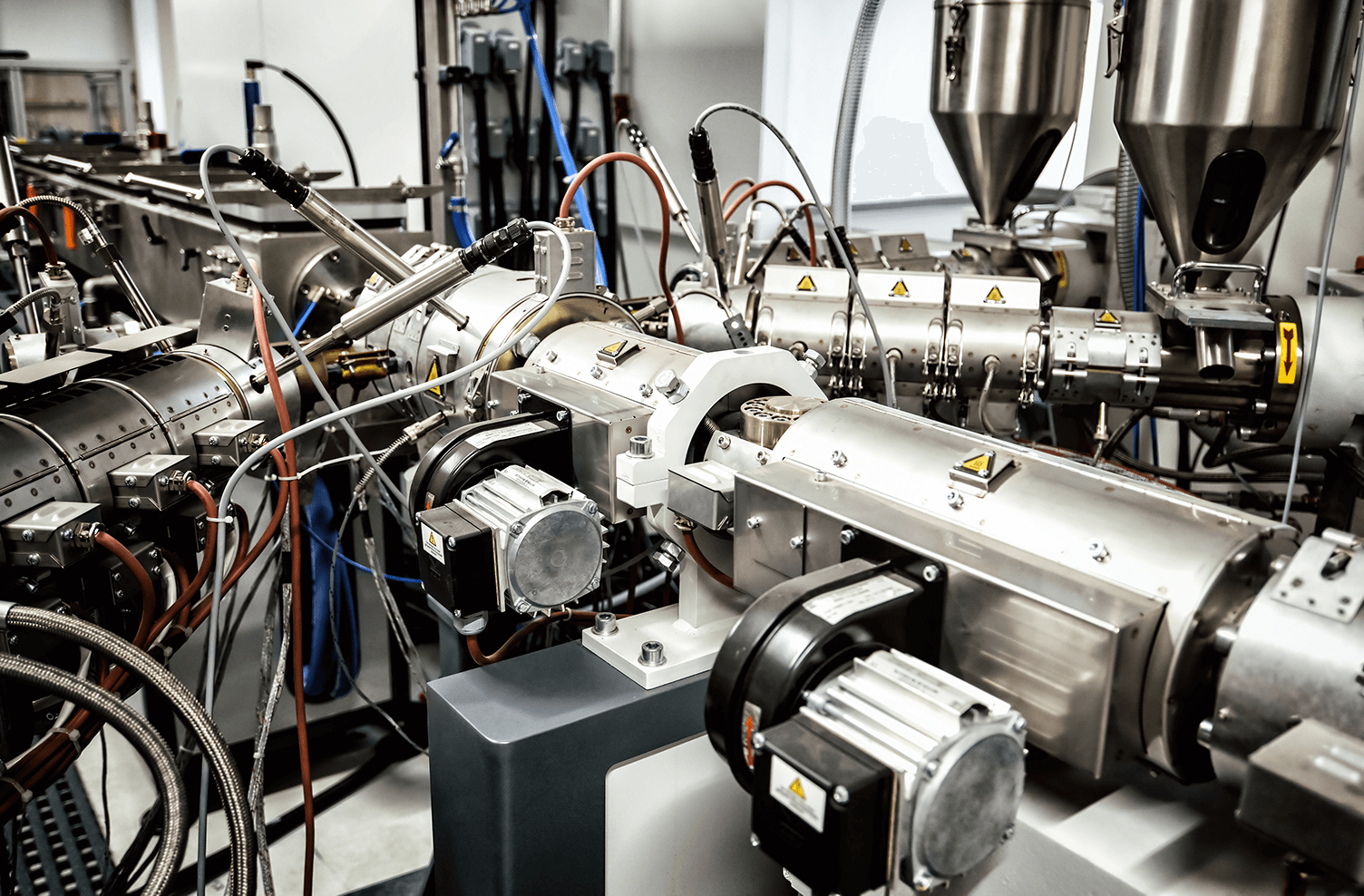

What is an extruder?

An extruder is a device that allows processing a wide range of synthetic materials and other materials used in manufacturing. The plasticizing system of an extruder is capable of extruding these materials and mixing them in a thermal process. The resulting substance then passes through the forming system. This makes it possible to give it any shape, such as a rod, tube, film, etc. After all this process, we get a finished and properly formed product further known as extrudate.

Plastic ext rusion is used in chemical processing, agri-food processing, pharmaceutical processing, paper processing, waste disposal and many other industries. Depending on the design of the cylinder and screw, extruders allow processing of polymers as well as plant raw materials. The design of extruders is adapted to the needs of individual production processes and different operating conditions of the equipment, in order to achieve the best possible performance. The basic types of extruders are: single and twin-screw, conical and parallel, co-rotating and counter-rotating.

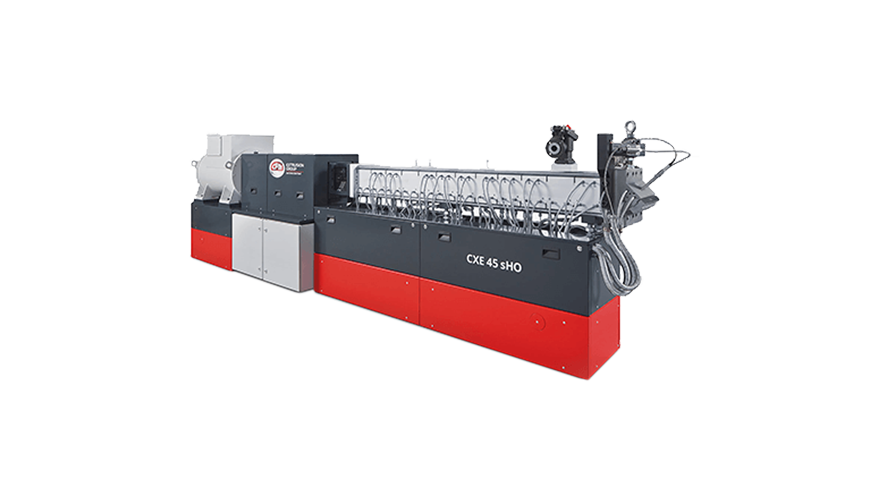

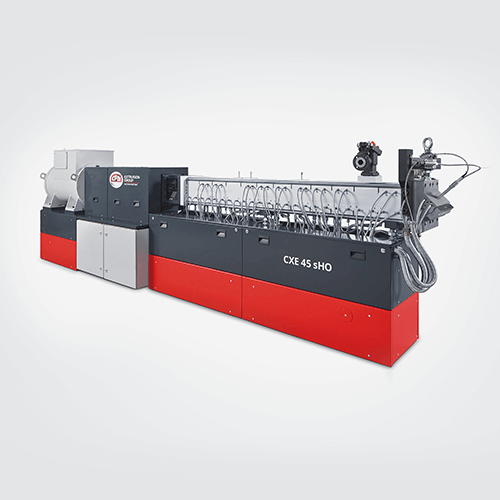

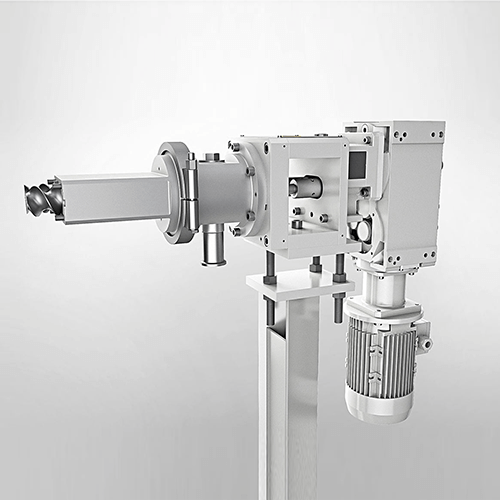

CXE series

Is a benchmark in the industry in terms of quality and reliability. Focusing on customer requirements, the series has been developed over 25 years. CXE machines are designed for maximum flexibility, efficiency and ease of service. Applications: adhesives, direct extrusion, modified plastics, powder coatings and toners, premixes, reactive extrusion, PVC, XLPE and cable compounds.

Contact us

APEX Series

Excellent extrusion economics. The series provides low manufacturing costs and high quality while maintaining productivity and machine life. The series consists of two levels that differ in geometry, cost and screw speed: the Apex CX and the Apex RTX. Applications: adhesives, direct extrusion, modified plastics, premixes, reactive extrusion, PVC, XLPE and cable compounds.

Contact us

TSE Series

Produced for more than 25 years, it is a benchmark of quality among basic class machines. It is one of the most widely used twin-screw machines on the Asian continent. The TSE was developed to maintain the same level of throughput and quality at optimum cost. Applications: adhesives, direct extrusion, modified plastics, premixes, reactive extrusion, PVC, XLPE and cable compounds.

Contact us

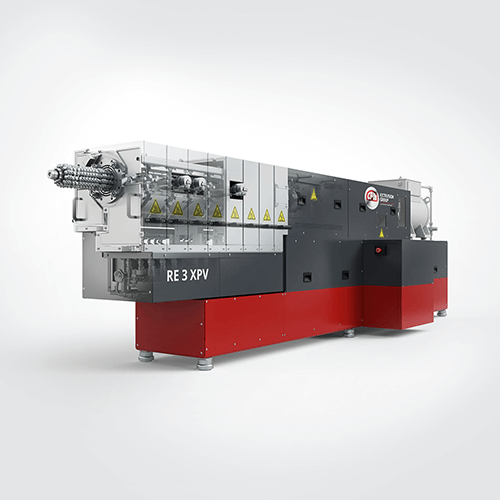

RE® RingExtruder Series

These are for demanding processes such as continuous rubber mixing, R-PET extrusion, adhesive extrusion, reactive extrusion, etc. Applications: continuous rubber mixing, PET recycling, adhesives, reactive extrusion, pharmaceutical industry, food industry.

Contact us

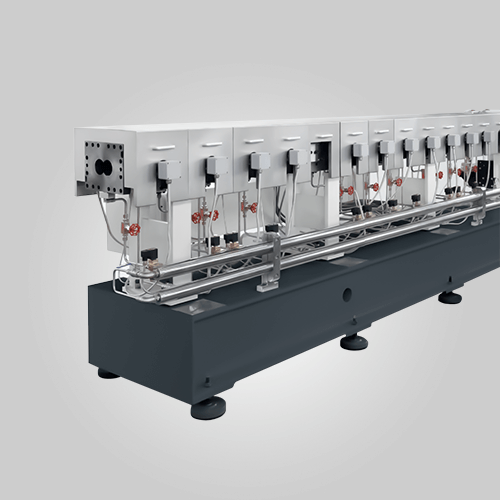

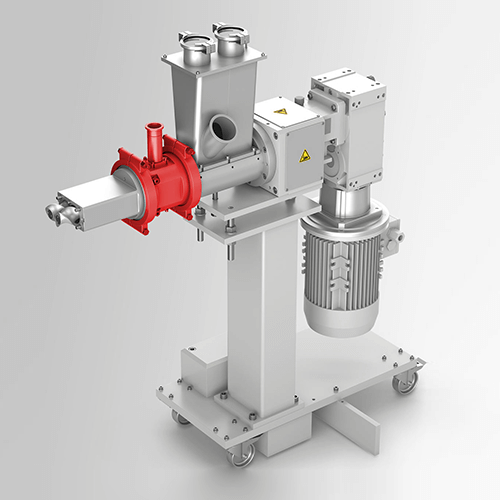

High-performance side feeder

Built to customer specifications to ensure increased productivity and product quality. The High Output Side Feeder easily adapts to any extrusion process of many OEM brands and more. With the new High Output Technology, powder can be added to the extruder while venting.

Contact us

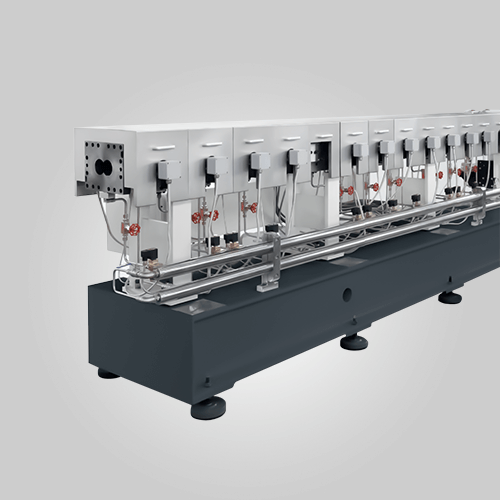

Degassing units

They achieve excellent results, even under the most difficult conditions and processing. Their design can be individually customized. CPM Extrusion Group’s degassing device can be mounted on an open or combination segment.

Contact us