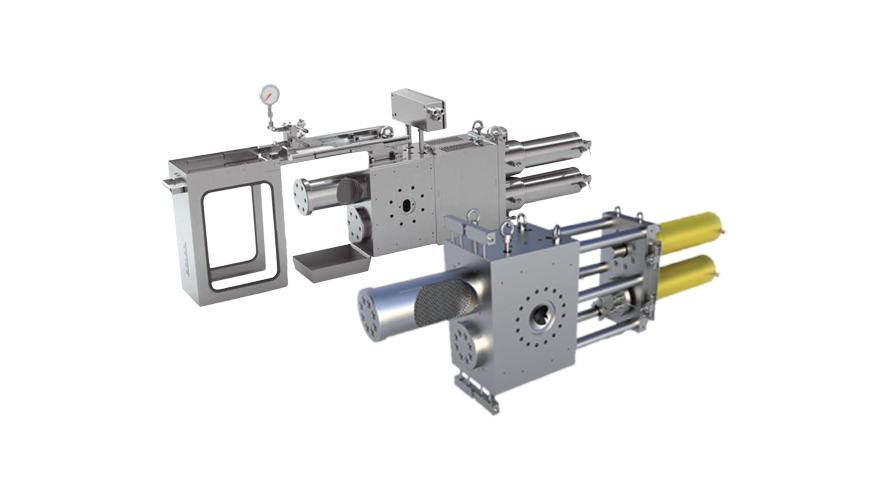

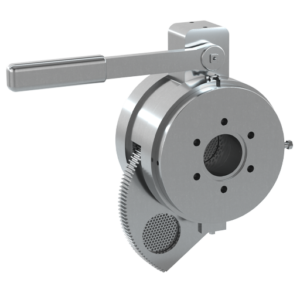

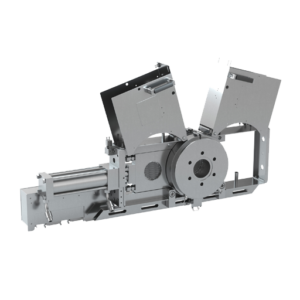

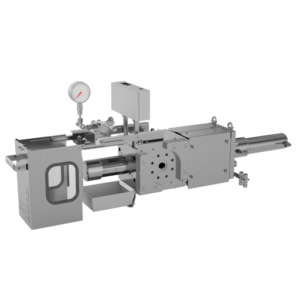

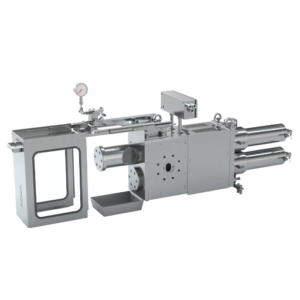

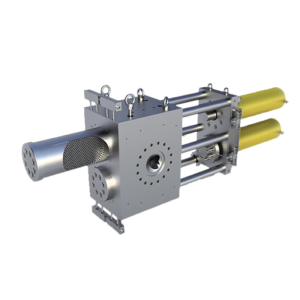

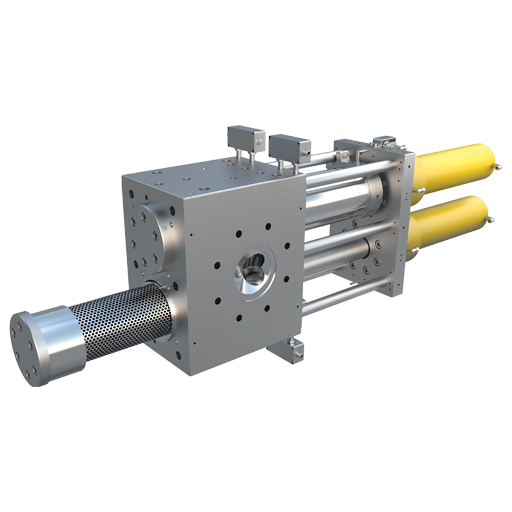

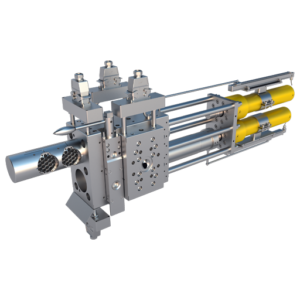

Any plastic extrusion process produces impurities, the presence of which can adversely affect the quality of the product, but can also hinder the process of the operation itself. It is therefore very important to ensure the best possible filtration, which will not reduce the quality of the extruded plastic. The screen changer eliminates to a very high degree any impurities in the polymer

Melted plastics and their solutions contain impurities of various sizes. These impurities include: molds from catalysts, wear and tear of mechanical parts, detached and burnt residues of material located between the cylinder and the screw, corrosion and others. However, most impurities are found in regranulates and plastic additives such as dyes, pigments and fibers. In addition, the following should be named as impurities in the plastic: incompletely polymerized plastic, unmelted granules and easily deformable gels.

The above impurities should be eliminated or separated from the plastic because:

- diminish the quality of the final product

- reduce the tightness and quality of the film

- decrease electrical strength in cable jackets

- decrease the strength of fibers and films and other products

- increase surface roughness

- accelerate aging of the material

- change optical properties (color)

- affect the wear of parts, such as nozzles, plastic pumps and others

Advantages of changers include:

- short flow time of the plastic through the filter channel allows rapid change of color or polymer grade

- screen changers (plate type) are characterized by ease of use and high durability of their components

- screens can be changed during operation of the entire processing line (on the run)