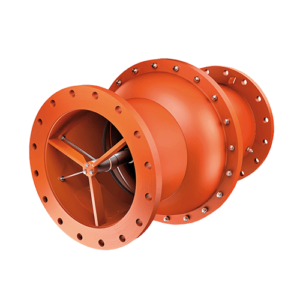

Shut-off valve

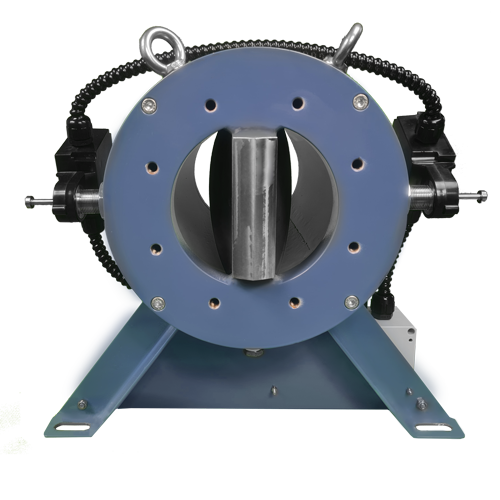

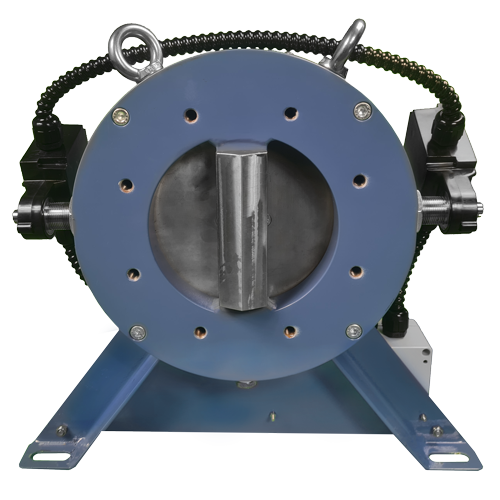

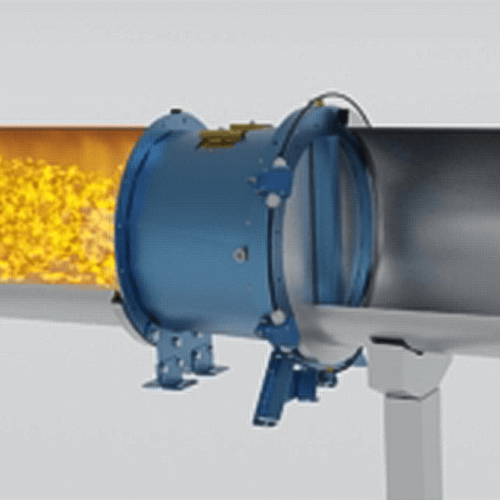

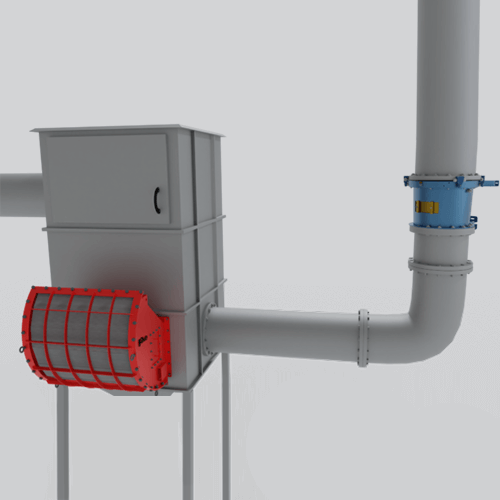

The DFI explosion-proof valve operates passively (flow-actuated), meaning that no external energy is required to close the valve flaps when deflagration occurs. When process air flows during normal operation, the air pulls or pushes the valve flaps open, allowing air to flow from the process into the protected equipment. When deflagration occurs in the protected device, the explosion pressure generated reverses the process air flow, closing the valve flaps and preventing the deflagration flame front from entering.

The DFI explosion-proof valve is designed in accordance with the requirements of NFPA 69 and EN 16477. The main components of the valve include heavy-duty welded steel construction, two isolation flaps, removable inspection hatches, flap latch assemblies and ratchet position indicator sensors for process stopping.

Wide range of applications, suitable for almost any application, it will find use in almost any industry.

Reliable double-locking mechanism

Unlike other flap valves that have failed identical flame isolation tests, it has been proven to withstand pressure differences and oscillations that “push and pull” a closed flap.

Flexible installation

Occupies a small footprint and can be installed in horizontal and vertical orientations. Can be located closer to the tank than other flap valves.

Wide range of protective capabilities

It can withstand the high pressures associated with almost all types of dust: organic dust ST1 (grain, coal, sugar, flour), organic dust ST2 (chemical, pharmaceutical) and metal dust (aluminum, iron, zinc and other alloys ).