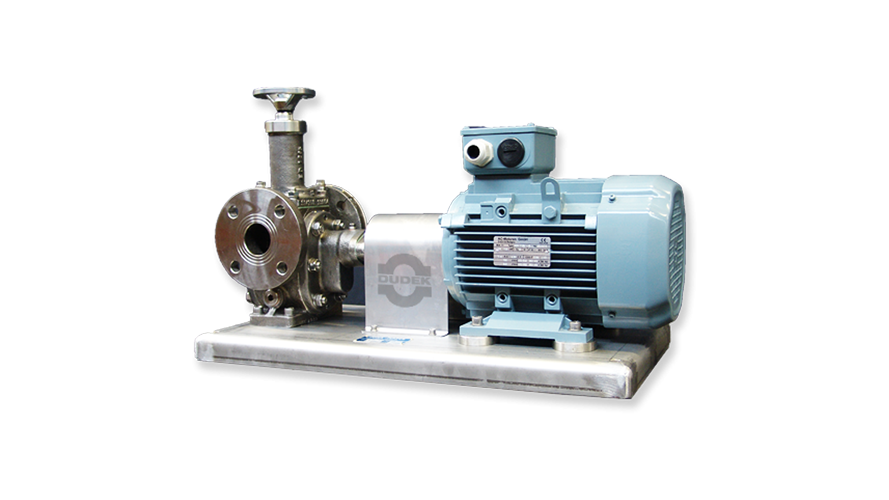

Dudek acid-resistant pump for chemical applications

1. Characteristics

DCP gear pumps used in process engineering are ideal for heavy viscous media pumping applications.

2. Construction

DCP series pumps are made of cast iron as a standard, but for corrosive media it is possible to make the pump from solid acid-resistant steel.

3. Purpose

Our pumps are used in many industrial applications. They are ideal for heavy chemical media as well as food, pharmaceutical and cosmetic applications.

4. Advantages

The performance of our pumps is proportional to the respective speeds, but depends on the differential pressure, speed level and viscosity.

DCPs are solid stainless steel gear pumps designed for demanding applications in the chemical, pharmaceutical, cosmetic and foodstuff industries. The large grading, design layout, various sealing systems and material combinations create that the pump can be used in a very wide range. For non-corrosive media, the model is offered in steel and cast iron.

DCP-G gear pump

DUDEK gear pumps can be made with three different sealing systems:

- DCP-EIG pump: single, internal mechanical seal;

- DCP-EAG pump: single, external mechanical seal;

- DCP-DG pump: double, mechanical seal.

DCP-MD gear pump

DUDEK gear pumps with magnetic coupling allow use for media hazardous to man and the environment. They are used primarily where mechanical seals fail or cause high costs.

DCP-H gear pump

As an option, the DCP series pumps can be with a heated casing:

- DCP-H: with electric heating of the casing (4 heating inserts in the casing);

- DCP-FH: with liquid or steam heating of aluminum plates, heating the upper and lower sides of the pump.

DCP-V gear pump

As an option, DCP series pumps can be supplied with a bypass valve. Such a valve protects the pump from excessive pressure increases.