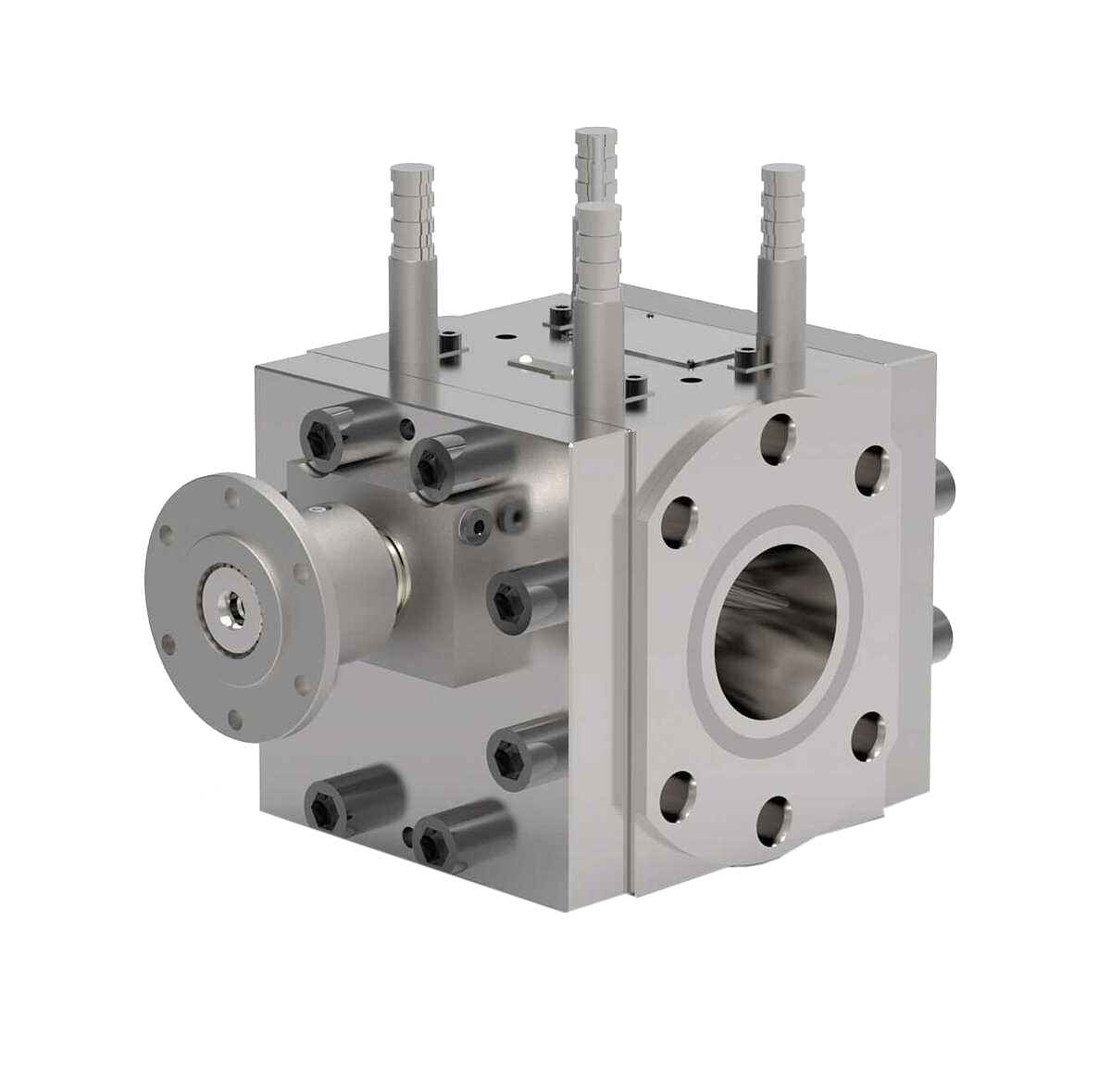

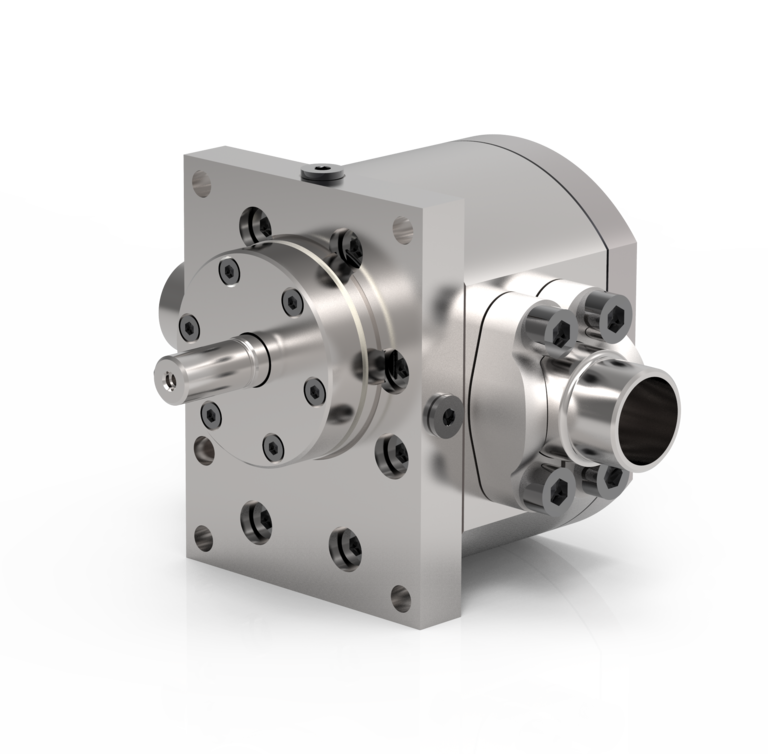

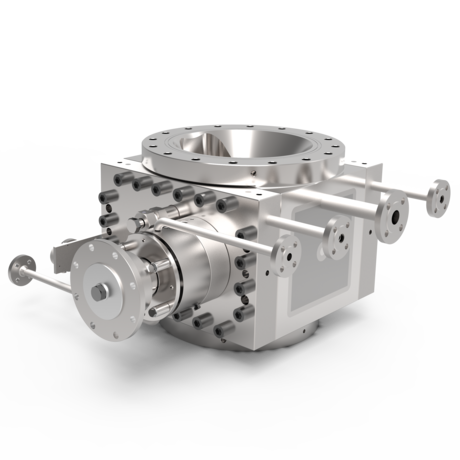

Polymer discharge pumps

Reliable and robust pumps are needed to empty reactors and containers particularly during the polymerization process The pumps transport the melt throughout the process. The highly viscous material must be transported from a reactor under vacuum. Discharge pumps from the POLY series from WITTE are specifically created for this task. The customer can choose between a standard design or an individual design according to their requirements.

Discharge pumps for polymerization production

These pumps achieve the best efficiency through optimized shaft and bearing geometry. The need for energy is kept low allowing the operating costs to be optimized. The POLY is offered in different variations. Versions with classic or shortened inlet geometries are just as possible as versions in the LowNPSH Design.

Pumps with shortened inlets guarantee the quick feed of melt to the gear pumps. All POLY discharge pumps have the largest possible inlet openings with optimized flow geometry to avoid increased friction, decelerated inlet of the medium into the pumps as well as to reduce additional heat input. Different material combinations make these pumps reliable partners in the polymer industry, which can also be operated reliably under the most extreme of conditions.

Technical data

| Housing | Unalloyed and alloyed steel · Cast steel · optional with coating |

| Gearwheels | Nitrided steel · Tool steel · Special steel · optional with coating · Helical gearing · Herringbone gearing |

| Axial shaft seals | (Vacuum) threaded shaft seal · Stuffing box · Combination of threaded shaft seal and stuffing box · double, locked mechanical seal |

| Heating | Heat transfer oil · Steam |

| Friction bearings | Tool steel · NiAG (nickel-silver) · Al bronze · Special materials · optional with coating |

Operating parameters

| Viscosity | Up to 40.000.000 mPas |

| Temperature | Up to 350 °C |

| Suction pressure | Vacuum up to max. 15 bar |

| Transport pressure / differential pressure | Up to 250 bar (4642 psig). The values listed are standard values and must not coincide under certain circumstances. Other values are available upon requests. |

| Pump dimensions | From 4.7-22-22 (4.7 ccm/rev – 10 kg/h) to 25,000-360-360 (25,000 ccm/rev – 52,000 kg/h). Sizes with wider gear pumps for lower differential pressures are available by default, for example, 3,170-152-254 (3,170 ccm/rev). |

Application examples

| Plastics | PET · PA · PBT · PC · PS SAN · ABS · HIPS · PP · PE · POM |

Industries

Plastic industry

Plastics production – Gear pumps for conveying plastic melts.