Cable glands

Cable glands are electrical devices that are used to protect electrical cables in explosion-prone areas. These glands contain special materials that prevent the spread of sparks and electrical arcs, which could cause an explosion. Cable inlets for hazardous areas are mainly used in the chemical, refining, petroleum and other industries where there is a risk of explosion due to the presence of flammable gases, liquids or dust.

Cable inlets are an important component of electrical installations in hazardous areas and play an important role in ensuring the safety and reliability of the installation. In hazardous areas where flammable gases, vapors, liquids or combustible dusts are present, electrical installations must meet strict safety requirements to prevent the risk of explosion or fire. Cable entries are an important part of these installations because they provide a safe and reliable connection between the cable and electrical equipment.

The purpose of cable entries is to protect the cable and the environment from potential hazards, while ensuring that the electrical circuit is complete.

Cable inlets are used in the process industry or where protection against hazards such as explosions or high temperatures is needed. Cable entries are mechanically assembled in such a way that the cable is sealed, providing grounding to the internal housing, which increases the mechanical strength of the cable connection and prevents loss of contact when vibration is present in the cable. They are also known as cable glands.

There are several types of cable entries suitable for explosive areas, including but not limited to:

1. Ex e cable entries:

Ex e cable entries are designed for use in areas where explosive gases or dust are present. These drains have a high level of electrical insulation and provide a safe mechanical connection between the cable and the equipment.

2. Ex d cable drains:

Ex d cable drains are designed for use in areas where flammable liquids are present. These drains are made of materials that are flame resistant and provide a safe mechanical connection between the cable and equipment.

To choose the right cable entries for hazardous areas, consider the following factors:

1. Hazard class:

Depending on the level of explosion hazard, choose the right cable entries, such as Ex e or Ex d.

2. Cable diameter:

Cable entries are available in different diameters, and you should choose the one that matches the diameter of the cable you are using.

3environment:

Consider the environment in which the cable entries will be used to make sure they are suitable for conditions such as temperature and humidity.

4. Connection requirements:

Considerconnection requirements such as pressure and mechanical load to make sure the cable entries are suitable for the application.

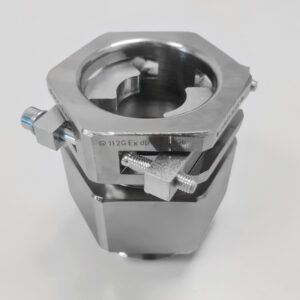

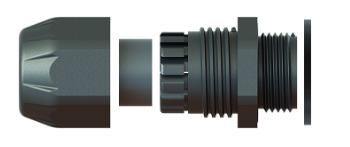

Cable entries consist of the following components:

- Entry point

- Sealing ring

- Filling compound

- Branch point

Special features:

- very high protection class IP66/IP68 (6 – protection against ingress of solids/dust and 8 – protection against water)

- for use in temperatures from -40°C to 100°C,

- for use in temperatures from -60°C to 1400°C,

- available in sizes: M12-M110 and NTP ¼” – NPT 4″

Cable inlets are subjected to type testing, which includes:

- checking the documentation with the standard and the test object with the documentation

- climatic exposures and mechanical tests

- tests with explosive mixtures (measurement of reference pressure, test of protection against flame transmission

- thermal testing

- tightness test

Standard cable inlets

Cable inlets for proper use in industrial areas

EMC cable inlets

Cable entries for simple and EMC-compatible shielded cable mounts

Ex cable entries

Cable entries for proper use in potentially explosive atmospheres