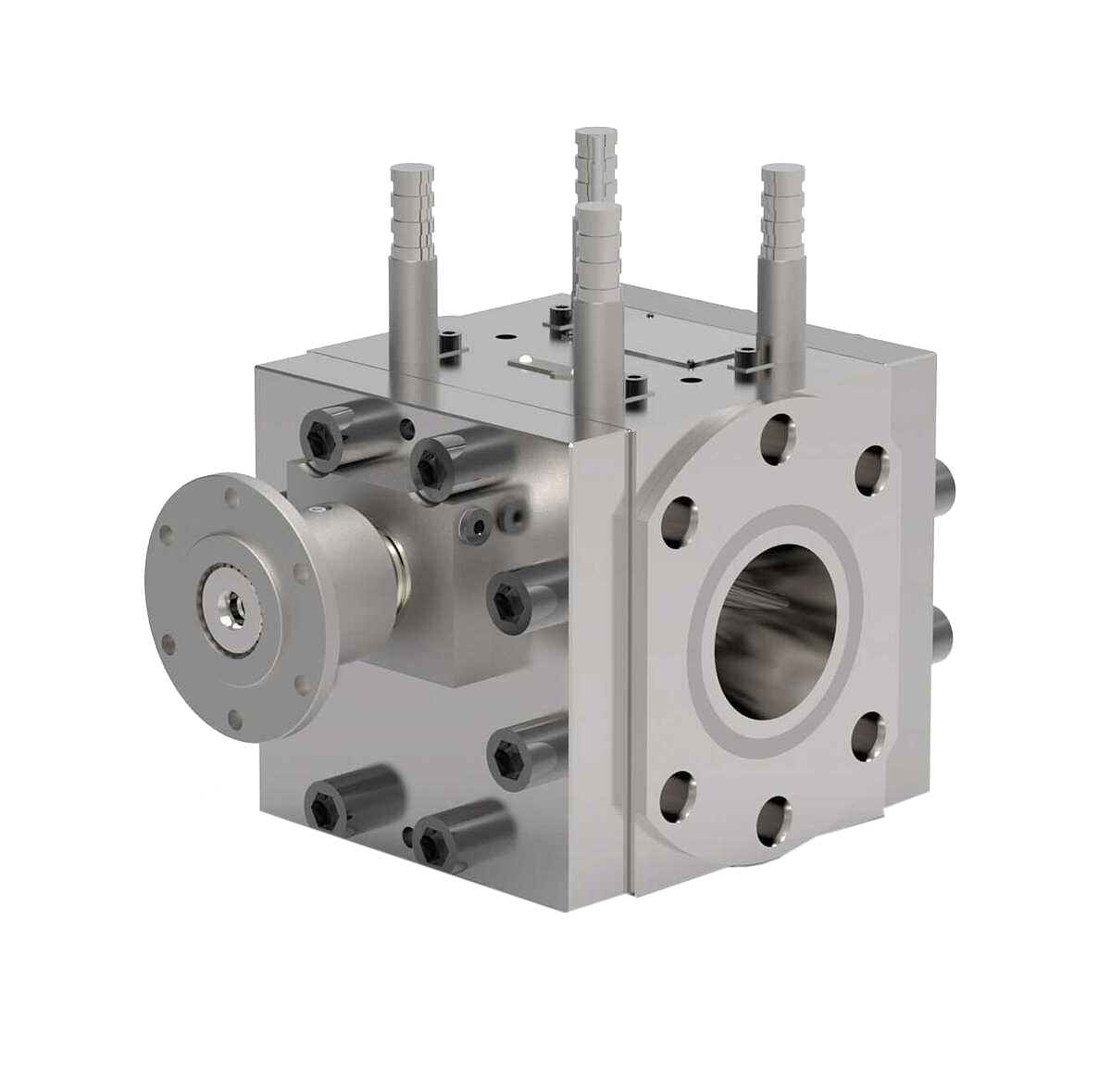

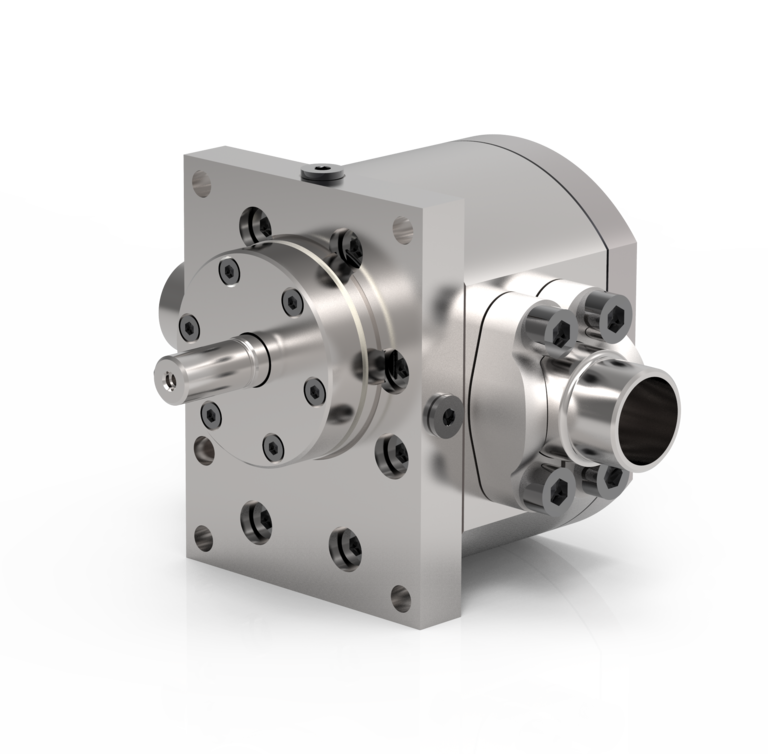

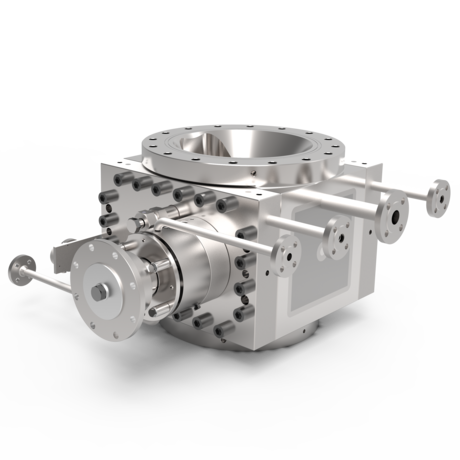

Gear pumps for pressure increase

The reliable pressure increase pump for the polymer process.

BOOSTER gear pumps from WITTE are used in the polymerization process to increase the pressure of medium to high viscous media. The hydraulically heated booster pump transports prepolymers and polymers, such as PET, PBT, PS, ABS and many others, in a very gentle manner. The heating is done through heat transfer oil or steam.

The core components such as shafts and friction bearings come from the WITTE unit block building system. The pressure increase pumps from the BOOSTER series are used wherever particularly high pressure is needed for the process. High pressures are needed, among other things, for the granulation, fiber production or for spinning pumps. The design of the BOOSTER pressure increase pumps can be adjusted to the needs of the plant and the customer’s requests.

Technical data

| Housing | Heat-resistant carbon steel, for example, 1.6582 · Stainless steel 1.4313 · optional with coating |

| Gearwheels | Tool steel · Nitriding steel · Special steel · optional with coating · Helical gearing · Herringbone gearing (for transportation with very low pulsation) |

| Shaft seals | Threaded shaft seal · Stuffing box · (Vacuum threaded shaft seal) |

| Heating | Heat transfer oil · Steam |

| Friction bearings | Tool steel · NiAG (nickel-silver) · Al bronze · Special materials · optional with coating |

Operating parameters

| Viscosity | Up to 40.000.000 mPas |

| Temperature | Up to 350 °C |

| Suction pressure | Vacuum up to max. 120 bar |

| Transport pressure / differential pressure | Up to 250 bar (4642 psig). |

| Pump dimensions | From 4,7-22-22 (4,7 ccm/U – 10 kg/h) to 12.000-280-280 (12.000 ccm/U – 30.000 kg/h) |

Application examples

| Polymers | PET · PBT · PA · PC · PS · SAN · ABS · HIPS · PP · PE · POM · Biopolymers |

Industries

Rubber & natural rubber

Gear pumps for rubber and natural rubber processing

Plastic industry

Plastics production – Gear pumps for conveying plastic melts.

Compounding

Gear pumps for compounding.