Rotary valves | Target dispensers | Target feeders

Rotary valves, also known as cellular valves, are devices that are used to transfer various types of powder or granules, such as sugar, cocoa, starch, flour, chemical ingredients, lime powder, clay, ash or wood chips.

The proposed dispensers on offer at CORONA are configurable with a myriad of standard parts. Thanks to this, these devices will stand up to even the most difficult conditions of working with various types of powders. Their robust design and high performance meet the requirements of the most advanced systems and process systems for bulk materials. The outlet space between the shaft seal and external bearings makes the dispensers ideal for high temperature applications. The entire range of units available is ATEX 2014/34/EU certified.

The dispensers have a coating that provides varying degrees of wear protection when handling abrasive products such as ash or minerals. We also supply a wide range of stainless steel rotary valves designed for use in the pharmaceutical and food industries. These units are made in accordance with Directive EC1935/2004. Where frequent, regular cleaning and sanitization of the interior is required, quick disassembly versions are available, equipped with guides for easy and safe removal of the lid and impeller. Special seals and special accessories for CIP (Clean in Place) cleaning are also available upon request.

In fact, the application possibilities for cellular dispensers are very wide, both in heavy industry and in other branches of production. For detailed information on individual models/types and their use, feel free to contact our experts.

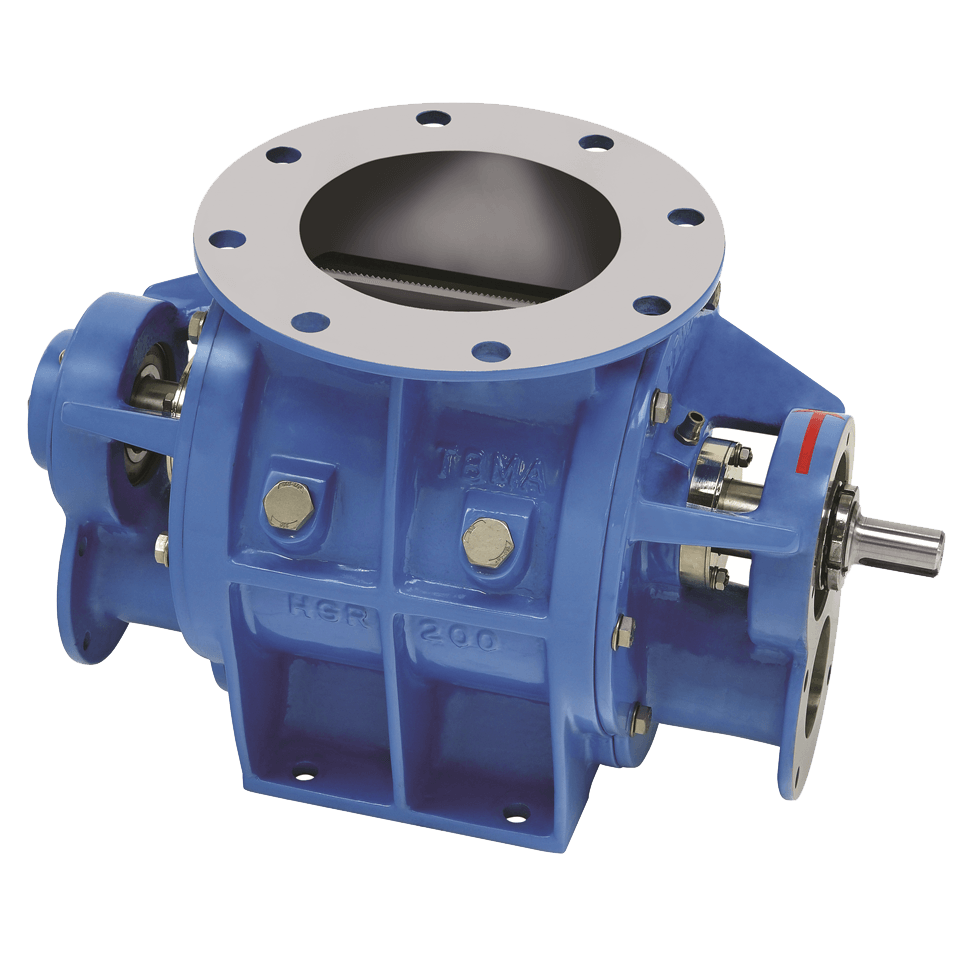

Target valve – H-AR

The H-AR type cellular dispensers have an optimally designed inlet that provides a high filling level and high capacity with minimal air leakage. Combined with a purge adapter or Venturi tube, these valves are suitable for minimizing the pressure differential in pneumatic conveying systems.

| Valve type | H-AR |

| Flange sizes (DN) | 15-500 |

| Rotor volume (ltr/rev) | 2,5-125 |

| Pressure differential | 1.5 barg |

| Standard design temperature | 120 °C |

| Internal ATEX Zone II 1/- D Ex h IIIC Da/- | Yes |

| Flame resistance | Yes |

| Explosion resistance | Yes (up to 10 barg) |

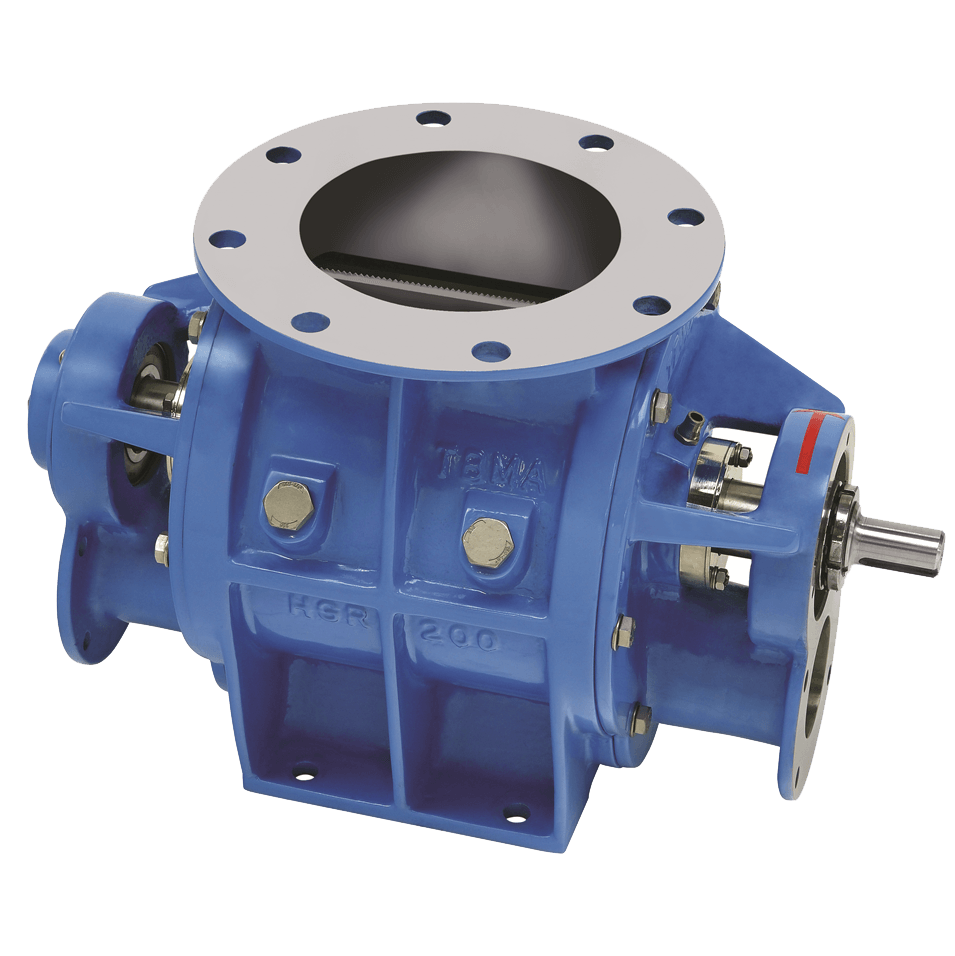

Target valve – H-GR

H-GR target dispensers are equivalent to H-AR valves and are used for direct product dispensing in pneumatic conveying systems in industrial applications.

H-GR target valves are equipped with connection flanges for direct installation in a pneumatic conveying line. These valves are a suitable alternative when insufficient space is available compared to a through valve with an adapter.

The integrated connections are adapted to the shape of the rotor, ensuring complete emptying of the rotor pocket. Cell valves are also equipped with vent holes as standard.

| Valve type | H-GR |

| Flange sizes (DN) | 150-350 |

| Impeller volume (ltr/rev) | 2,5-58 |

| Pressure differential | 1.5 barg |

| Standard design temperature | 120 °C |

| Internal ATEX Zone II 1/- D Ex h IIIC Da/- | Yes |

| Flame resistance | Yes |

| Explosion resistance | Yes (up to 10 barg) |

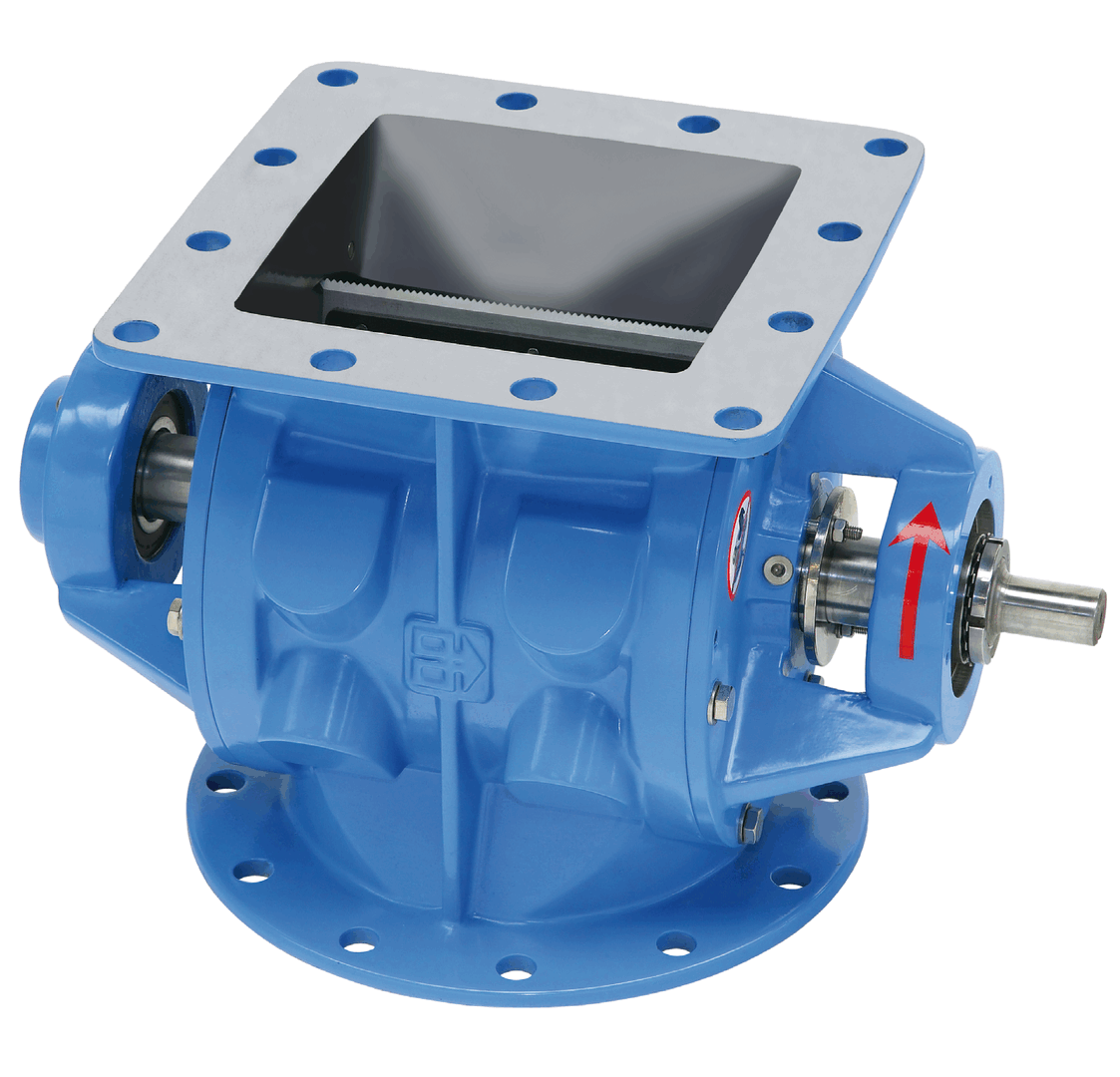

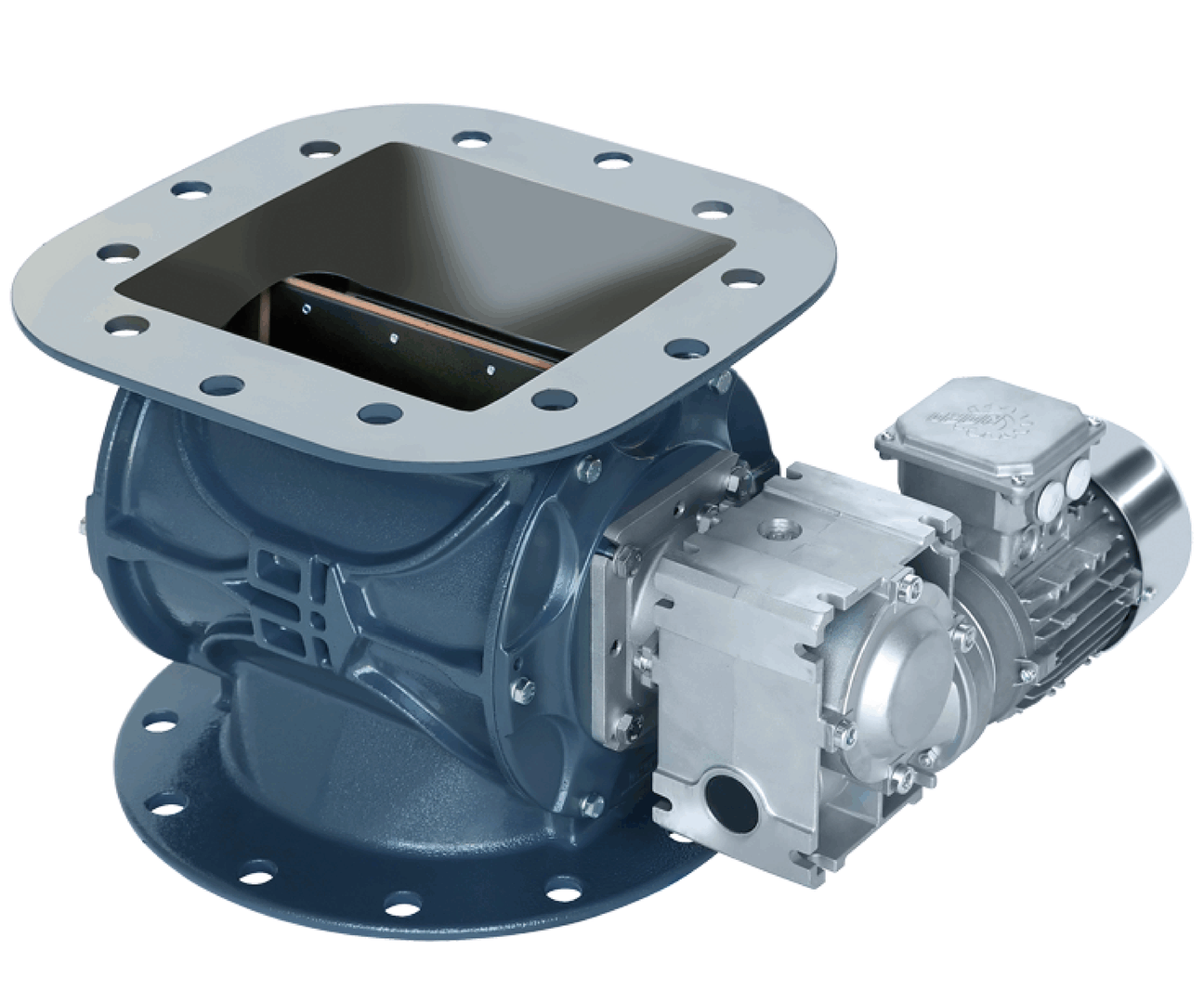

Target valve – H-AX

H-AX cellular dispensers are the equivalent of H-AR valves and are used when inlet size is more important than impeller volume. The relatively large inlet ensures that even the weakest flowing products are discharged efficiently. These valves are equipped with round and square inlet flanges. This allows the valve to be used as a transition piece from a round flange to a square flange or vice versa. This is beneficial for the installation dimensions and simplifies the installation process.

| Valve type | H-AX |

| Flange sizes (DN) | 150-350 |

| Impeller volume (ltr/rev) | 2,5-34 |

| Pressure differential | 1.5 barg |

| Standard design temperature | 120 °C |

| Internal ATEX Zone II 1/- D Ex h IIIC Da/- | Yes |

| Flame resistance | No |

| Explosion resistance | Yes (up to 10 barg) |

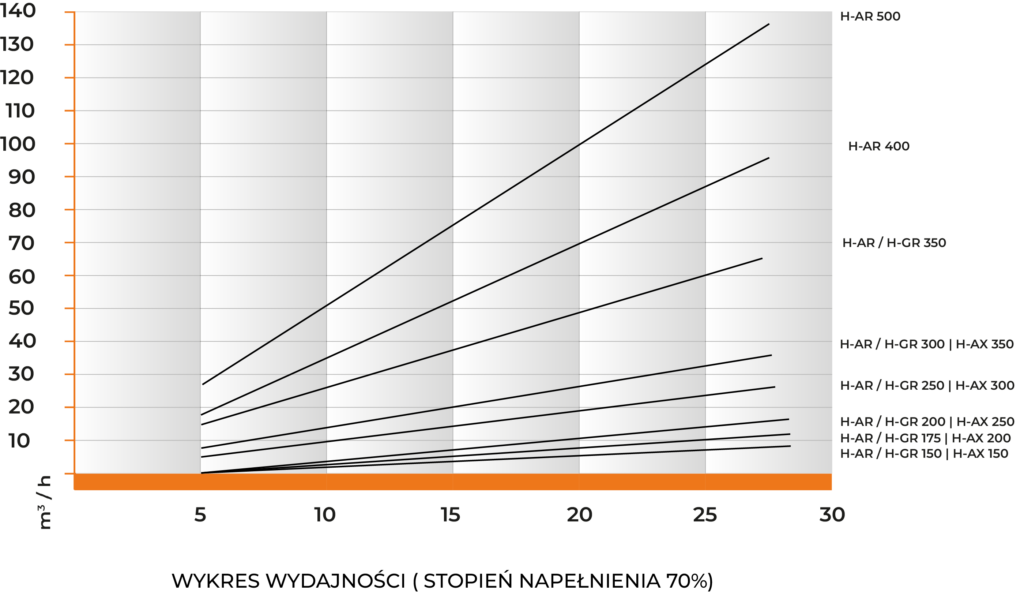

H-AR, H-GR, H-AX performance chart

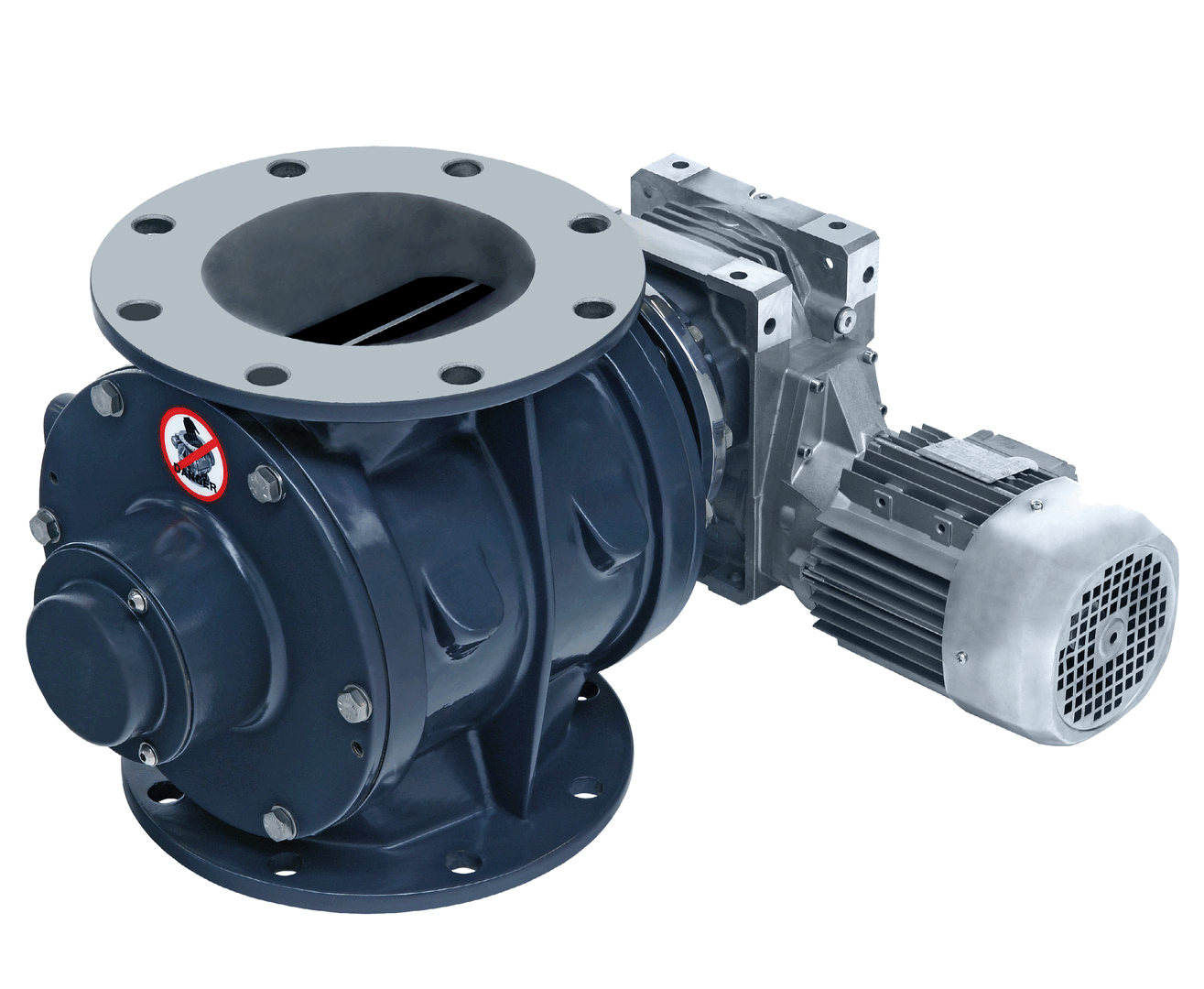

Target valve – S-AX

S-AX cellular dispensers are specially designed for use under filters and cyclones. They are used in applications where the pressure differential is up to 500 mbarg and the valve acts mainly as an airlock or explosion barrier. The S-AX valve can be used as a stand-alone protection system up to 2.5 barg for St1 and St2 dust class products.

The locks are made of GN40 ductile iron. This type of cast iron is stronger than conventional cast iron: it is much less brittle, making it more resistant to shock loads and has high corrosion resistance.

The installation weight of the S-AX system is only 65 kg. The result is a particularly favorable price/quality ratio for this type of valve. S-AX valves are equipped with a round and square connection flange, which allows the valve to be used as a transition element from round to square flange and vice versa.

| Valve type | S-AX |

| Flange sizes (DN) | 250 (round/square) |

| Rotor volume (ltr/rev) | 9,5 |

| Pressure differential | 0.5 barg |

| Standard design temperature | 70 °C |

| Internal ATEX Zone II 1/- D Ex h IIIC Da/- | Yes |

| Flame resistance | Yes |

| Explosion resistance | Yes (up to 2.5 barg) |

Target valve – M-AX and R-AX

The M-AX and R-AX target dispensers are designed for standard applications with limited differential pressure. These valves are used for dispensing non-abrasive materials under cyclones or filters and in low-pressure pneumatic conveying systems.

M-AX

M-AX valves are available in six sizes and are equipped with round connection flanges.

R-AX

R-AX valves are equipped with both round and square connection flanges. This allows the valve to be used as a transition element from a round flange to a square flange or vice versa. This is beneficial for the installation dimensions and simplifies the installation process. R-AX valves are available in five sizes.

| Valve type | M-AX | R-AX |

| Flange sizes (DN) | 150-350 | 150-350 |

| Impeller volume (ltr/rev) | 2,5-58 | 2,5-34 |

| Pressure differential | 1 barg | 1 barg |

| Standard design temperature | 80 °C | 80 °C |

| Internal ATEX Zone II 1/- D Ex h IIIC Da/- | Yes | Yes |

| Flame resistance | No | No |

| Resistance to explosion | No | No |