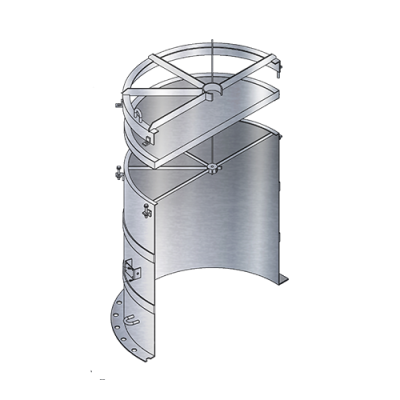

Flameless venting is a safety system used to prevent fires and explosions in storage tanks and other vessels containing flammable liquids and gases. Flame arresters are installed on top of explosion-proof dampers and contain multiple layers of high-temperature stainless steel mesh that absorb the heat of deflagration. By cooling the deflagration below the ignition temperature of the fuel, combustion is stopped and only pressure escapes from the device.

Flameless venting is widely used in the chemical, petrochemical and pharmaceutical industries to ensure the safe storage, handling and transportation of flammable liquids and gases. It is a reliable and effective method of reducing the risk of fire and explosion and protecting workers, equipment and the environment.