1. Characteristics

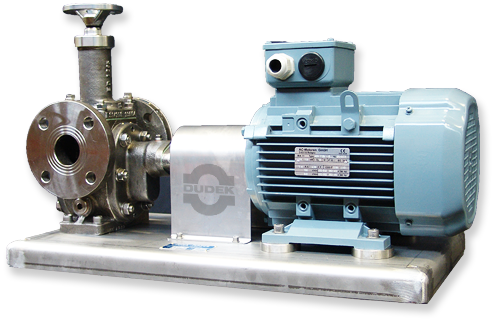

The I-IV series gear pump is the most popular model in DUDEK’s portfolio. The pump is ideal for chipboard production, asphalt pumping, as a wax pump, grease and oil pump, paint and varnish pumping and many other heavy-duty applications.

2. Construction

DUDEK pump housings are made of cast iron , ductile iron and various stainless steels or special alloys such as: Hastelloy. The material of gears and shafts is made of steel or stainless steel, respectively.

3. Purpose

The I-IV series pump will be suitable for chemical and petrochemical applications, as well as for pumping oil lubricants, but also as a chocolate pump. Its reliable operation makes it recognized in many production plants whether in Poland or around the world as a reliable positive displacement pump.

4. Advantages

The pumps can be operated in the gas explosive area of zones 1 and 2. In this case, the pump is given a separate configuration, and thus meets the requirements of EU Directive 94/9 Zone 2 II 3G and 2G Zone 1 II ( or from 04.20.2016 EU Directive 2014/34 / EU). In general, Dudek pump units meet the requirements of the Machinery Directive 2006/42 / EC and are supplied to EU customers with the CE mark.

| Type | Pressure flange | Speed | Capacity | Performance |

|---|---|---|---|---|

| Size | DN | [1/min] | [m³/h] | [l/min] |

| I/a | 32 / 32 | 1.500 / 1.000 / 750 | 3 / 2 / 1,5 | 50 / 34 / 25 |

| I/b | 50 / 40 | 1.500 / 1.000 / 750 | 6 / 4 / 3 | 100 / 67 / 50 |

| II/a | 50 / 50 | 1.500 / 1.000 / 750 | 10 / 7 / 5 | 167 / 117 / 84 |

| II/b | 65 / 50 | 1.500 / 1.000 / 750 | 15 / 10 / 7,5 | 250 / 167 / 125 |

| III/a | 65 / 50 | 1.500 / 1.000 / 750 | 20 / 14 / 10 | 334 / 234 / 167 |

| III/b | 80 / 65 | 1.500 / 1.000 / 750 | 25 / 17 / 12,5 | 417 / 284 / 209 |

| IV/a | 80 / 80 | 1.500 / 1.000 / 750 | 35 / 23 / 17,5 | 584 / 384 / 292 |

| IV/b | 100 / 80 | 1.500 / 1.000 / 750 | 50 / 33 / 25 | 834 / 550 / 417 |

| V/a | 125 / 100 | 1.500 / 1.000 / 750 | 60 / 40 / 30 | 1.000 / 667 / 500 |

| V/b | 150 / 100 | 1.500 / 1.000 / 750 | 80 / 53 / 40 | 1.334 / 884 / 667 |

| V/c | 150 / 100 | 1.500 / 1.000 / 750 | 90 / 60 / 45 | 1.500 / 1.000 / 750 |

| VI/a | 150 / 125 | 1.500 / 1.000 / 750 | 100 / 66 / 50 | 1.667 / 1.100 / 834 |