An industrial pump is a pump used for pumping dense and viscous media in various types of industrial applications. Industrial – gear pumps are characterized by pulseless and accurate flow, making them ideal for applications requiring precise metering.

See our industrial pumpsWhere do we use gear pumps?

Industrial pumps are ideal for handling dense and viscous liquids, such as in pumping:

- oil,

- emulsion,

- grease,

- asphalt,

- wax,

- glue,

- paraffin,

- resins.

They will also work well as pumps for chemicals or acid. They are also very often used as food pumps when transporting liquid chocolate or molasses.

Gear pump – principles of operation

The industrial gear pump is a device of uncomplicated, simple design. Inside the pump there are two shafts with gears mounted on them. An external drive sets one of the shafts in motion – the so-called drive shaft, which forces the other shaft to rotate. Gear pumps have the ability to draw fluid into the free spaces between the gear teeth. The fluid is then transported between these spaces and the pump housing – all the way to the pump output. Efficient operation of the device is ensured by a good fit of all components. The small spaces between the components of the pump, as a result, force the flow of liquid from the suction hole to the outlet.

Construction of the gear pump

A gear pump consists of:

- shafts with gears,

- the pump body,

- bearings and seals.

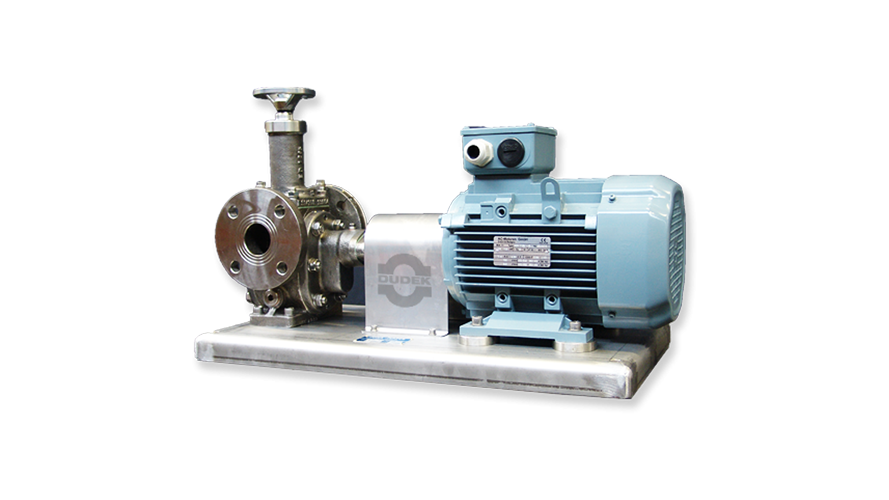

Dudek industrial gear pumps – characteristics

Thanks to their simple design and reliability, Dudek Pumps are perfect for almost all industries. Depending on the medium to be pumped, we can supply pumps in various material designs – from cast iron, to black steel, to special stainless / acid-resistant steels. In addition, our equipment is available in various shaft sealing options – with a string seal or mechanical pump seal. An additional advantage is the possibility of equipping the pumps with a special heating jacket, as well as specially selected electric heating, so that the devices can pump liquids that tend to stagnate at ambient temperature. The gear pump can also be equipped with an adjustable safety valve.

How do you select a gear pump for your application?

In order to ensure the efficient operation of a pump on a given industrial application, it is necessary to take into account all the technical parameters needed to select the most effective solution. Based on your completed pump selection sheet, our engineers will prepare a technical quotation specifically tailored to your industrial application.

We also offer pumps that can operate in the ATEX zone (ATEX pump, EX pump).

All our pumps are designed and manufactured in accordance with applicable standards.

The German company Dudek-Pumpen, based in Hamburg, has been producing gear pumps for pumping high-viscosity liquids for more than 75 years. Such a long period of the company’s existence is a solid guarantee of quality, standing at the highest global level.