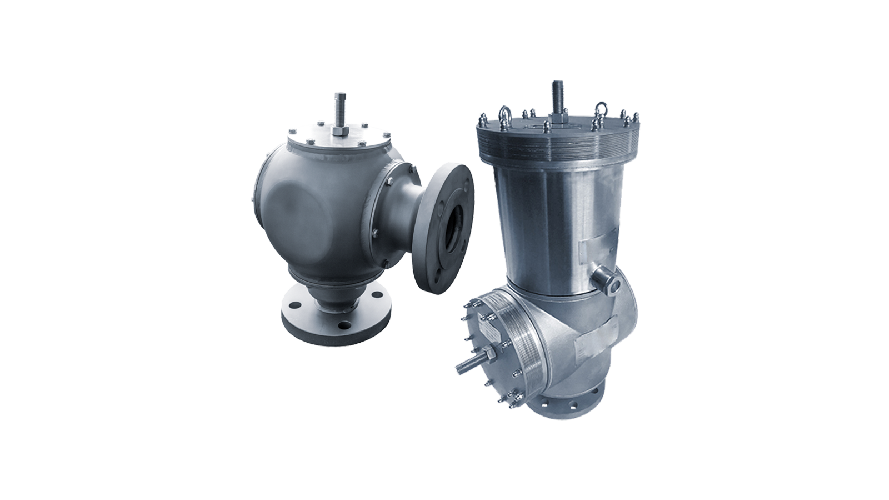

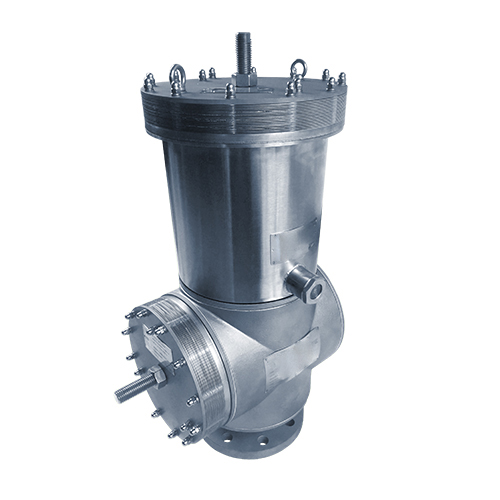

Breather valve – pressure relief valve

Breather valves provide direct protection of tanks and installations from the effects of exceeding critical pressure limits. Breather valves are mounted on tanks using flanged connections, sized to the required capacity and opening pressure.

All our valves are designed and manufactured in accordance with applicable standards. We have international experience supplying breather valves across Europe in the Middle East and Eastern markets.

Why do we use breather valves?

Inside a tank, the working pressure limit can be exceeded, which can occur for a number of reasons, such as thermal changes through excessive heating or cooling of the tank or during the pumping/vacuuming process. Such an increase in pressure, or vacuum, can unbalance the system or damage the tank, so it is important to control the pressure and allow the tank to breathe, eliminating the possibility of rupturing the integrity of the tank (explosion) or implosion.

Implosion is the opposite of explosion because of the direction of action. During it, the shock wave propagates inward, the opposite of an explosion. During this phenomenon, there is a sudden collapse of matter in an enclosed area. The breather valve allows for stable pressure operation during tank loading or unloading operations.

How do breather valves work?

Most tanks require a venting device to enable its controlled ventilation to allow a large volume of vapor/gas of the stored medium to escape at relatively low pressure.

Suction of gas (usually air), occurs when the medium is pumped out of the tank and the vapor condenses at a temperature lower than the ambient temperature. As a result, a vacuum is created, which must be eliminated, by replenishing the gas. The process of respiration is the opposite phenomenon and takes place when the tank is filled and the liquid is vaporized due to a temperature higher than that of the atmosphere.

Zobacz nasze zawory oddechoweOperating principle of the breather valve

Operating principle of the breather valve

1) external discharge of excess gas

2) the refilling of the gas inside the tank

Breather valve technical parameters:

• size range from DN 25 to DN 400

• opening pressure settings from 2 mbar to 500 mbar

• materials made of aluminium, carbon steel, stainless steel, hastelloy, plastic

The basic division of the breather valves concerns the direction of their capacity:

• pressure relief valves are designed to drain the excess gas to the outside of the tank/installation, thus preventing a tank explosion;

• vacuum valves are designed to replenish the gas shortage inside the tank / installation, thus preventing an implosion

• the vacuum/overpressure valves combine the design of the above valves inside one device

An additional advantage of the breather valves is the possibility to use their combination with flame arresters – a version with built-in flame arrester or as a certified set.

Breather valve with outlet flange

We also offer special valves with an outlet flange for the discharge of product vapors to the collecting pipeline (this pipeline must be secured individually). This solution enables the recovery of vapors or pre-vents the release of hazardous substances into the atmosphere.